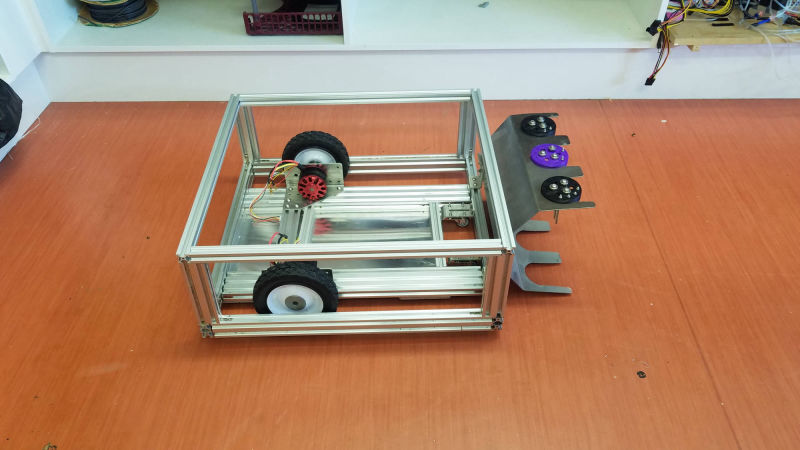

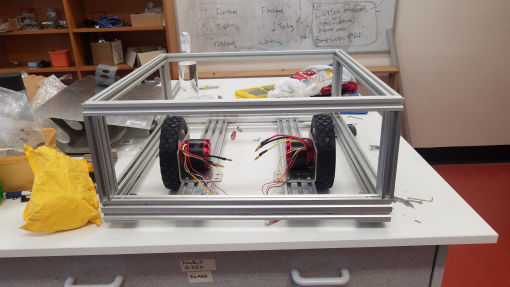

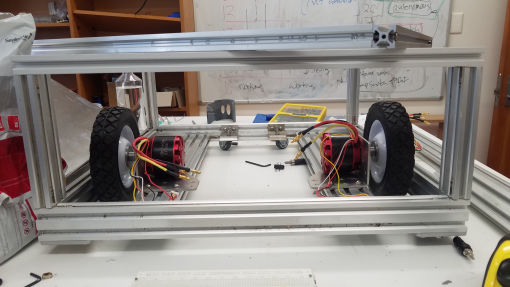

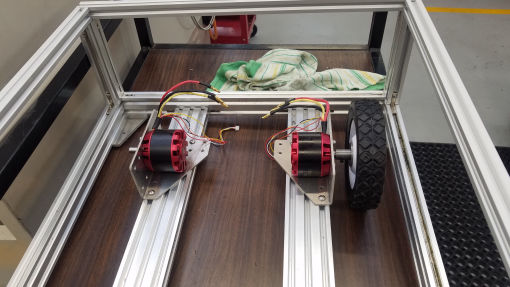

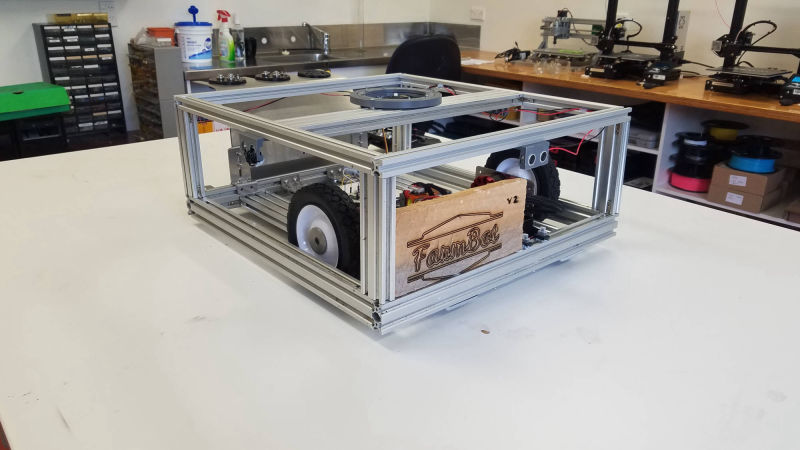

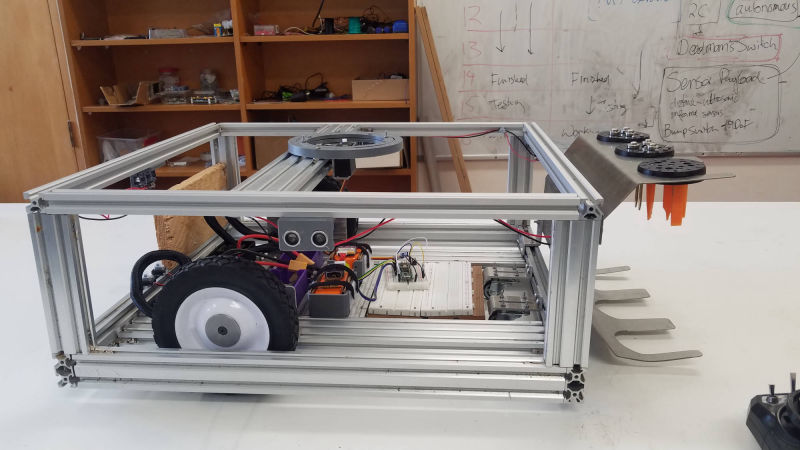

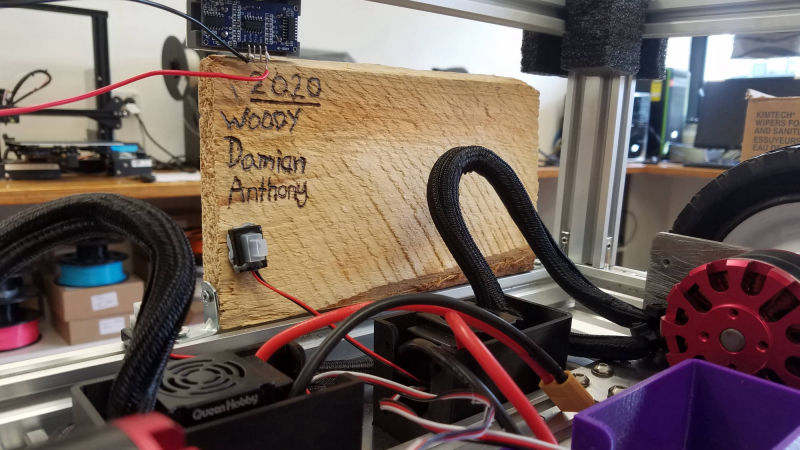

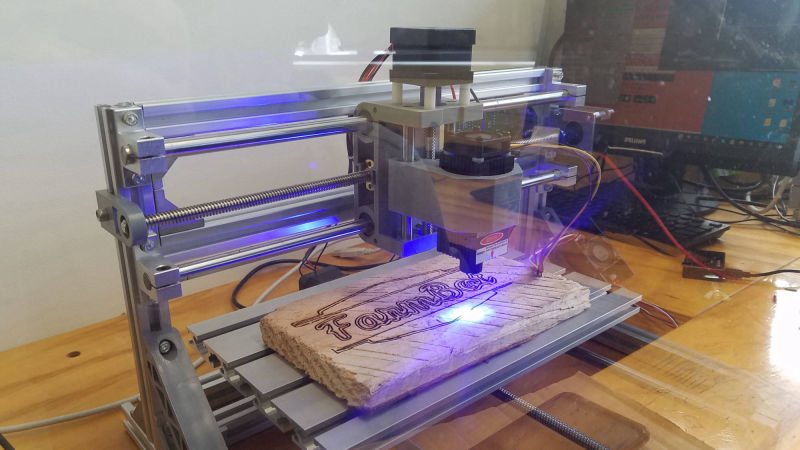

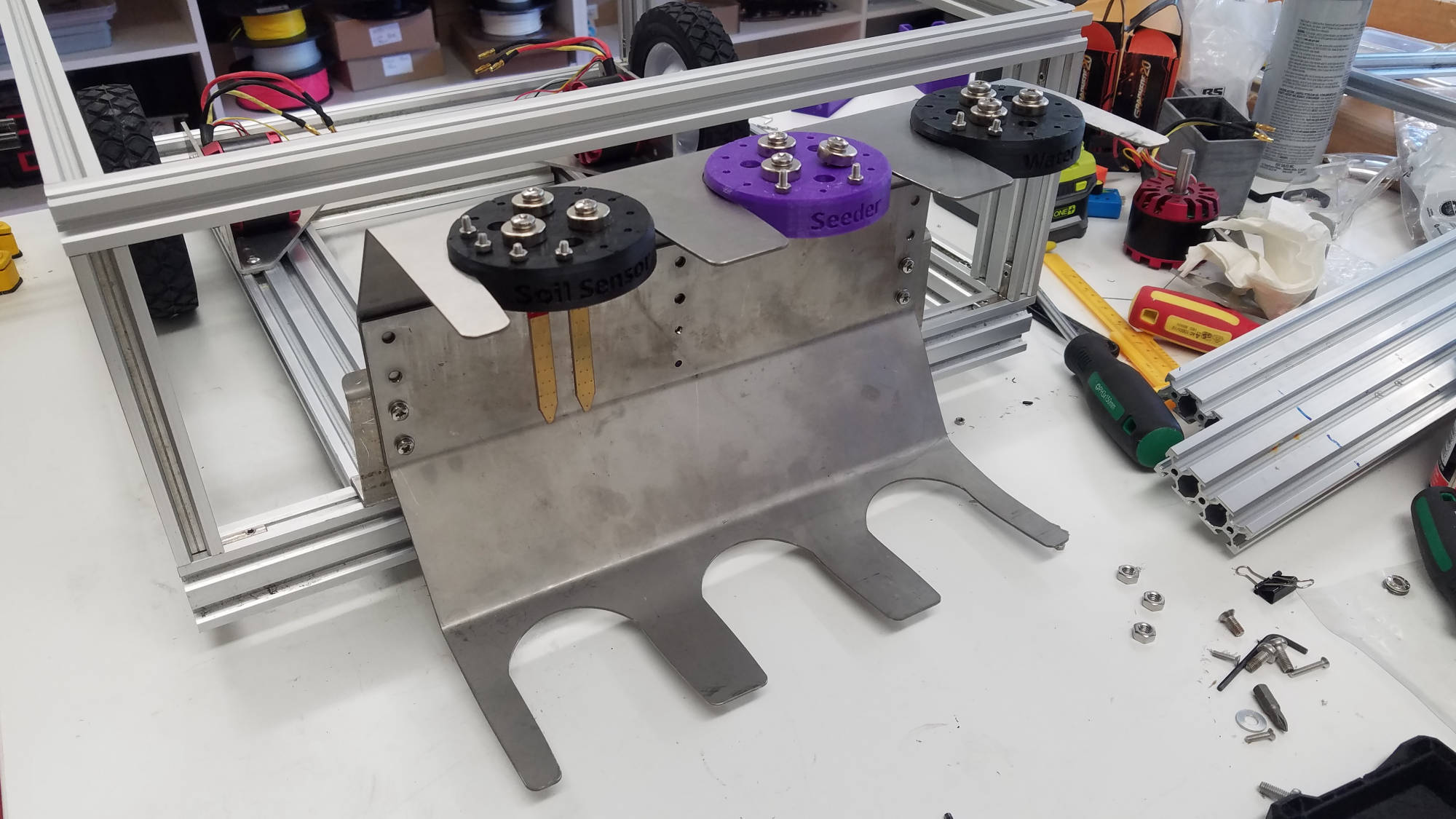

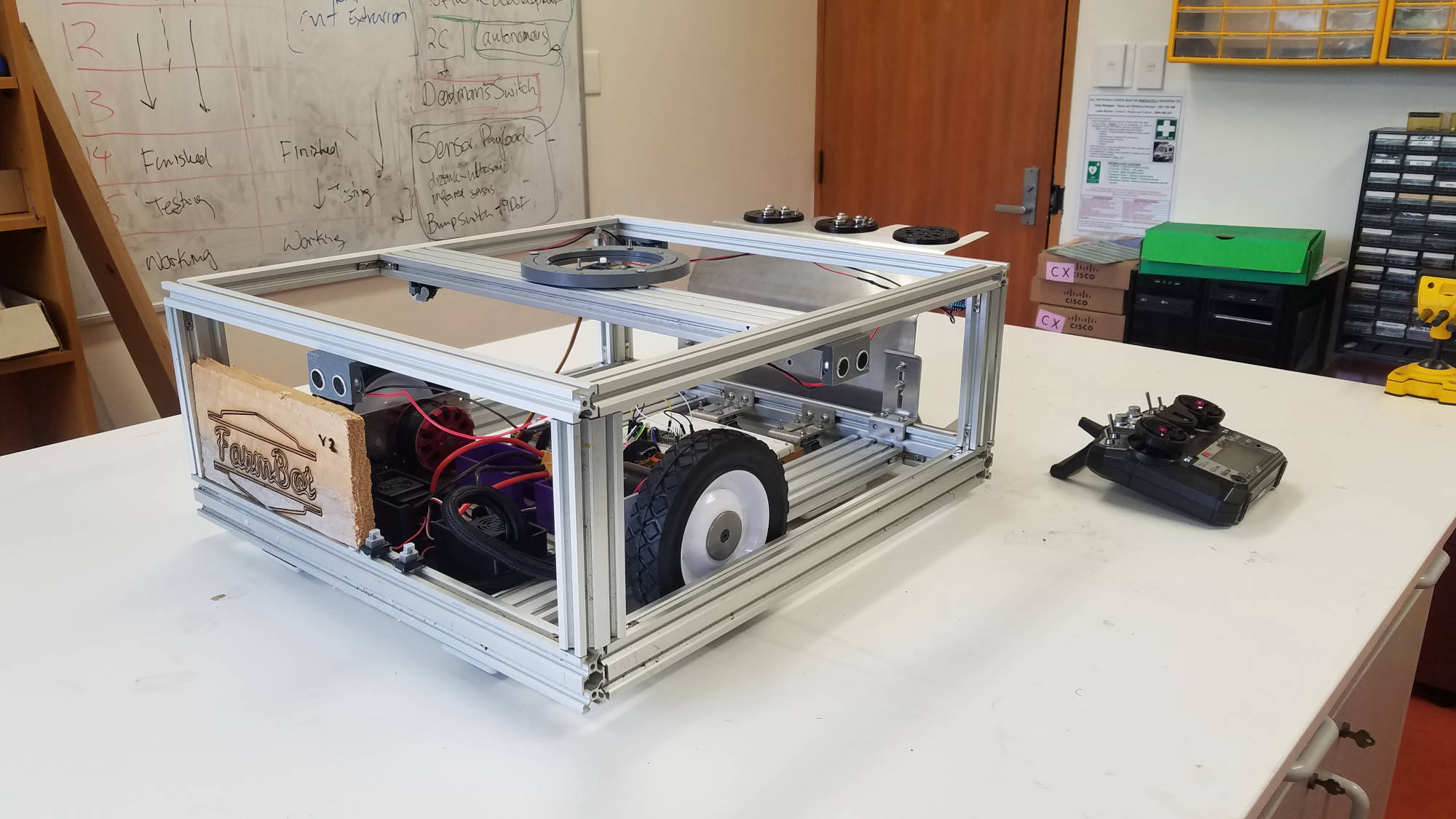

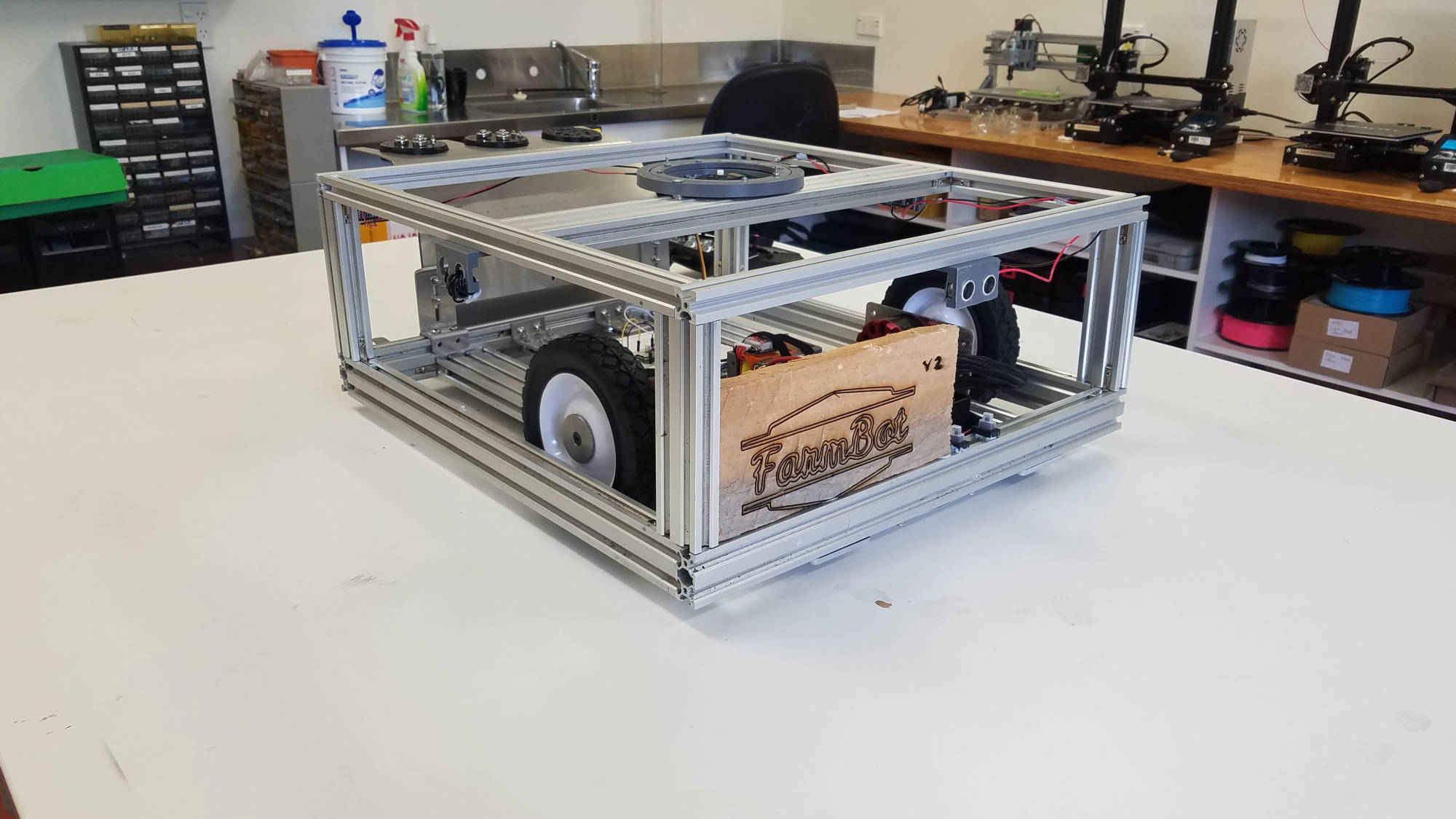

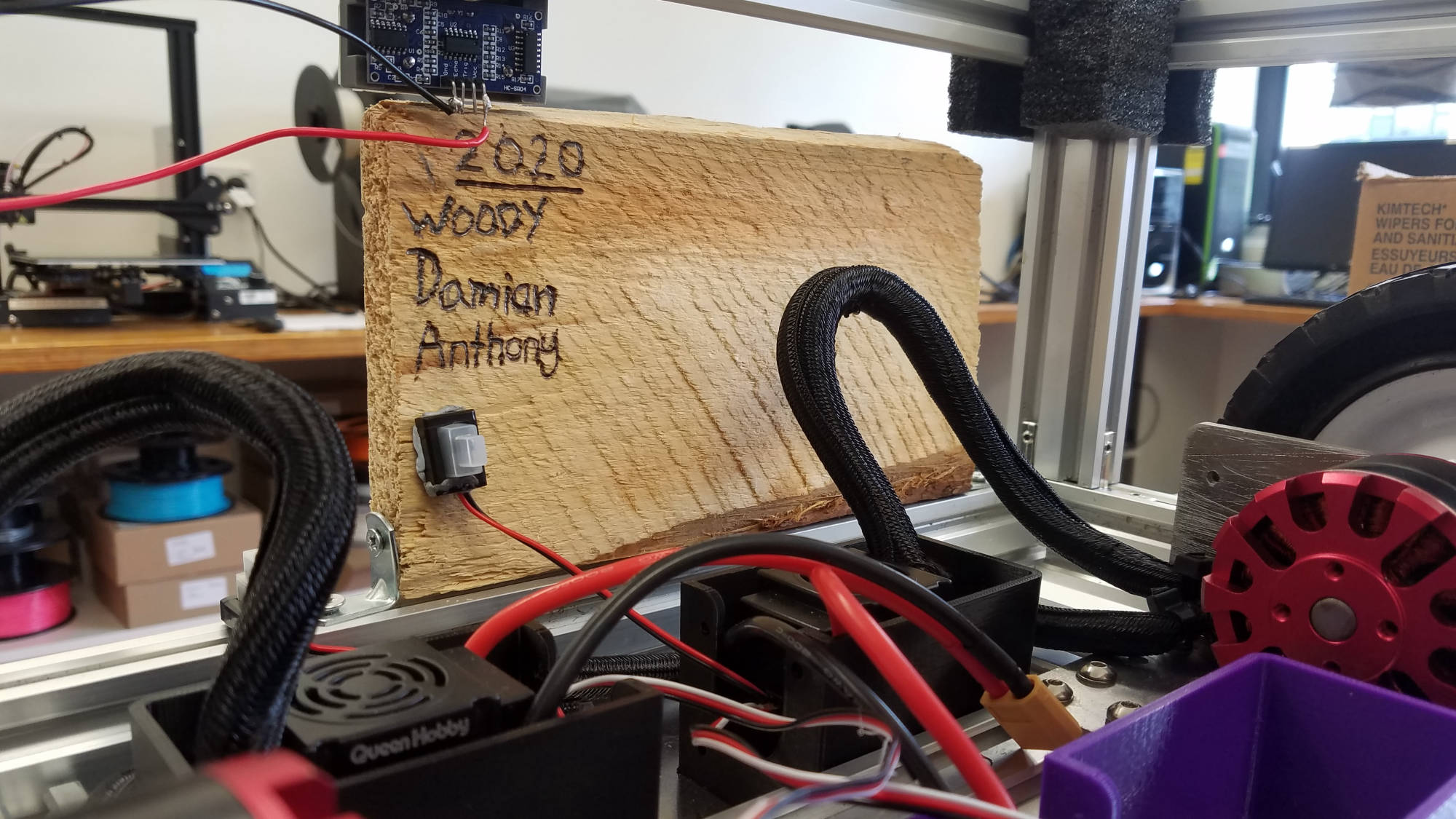

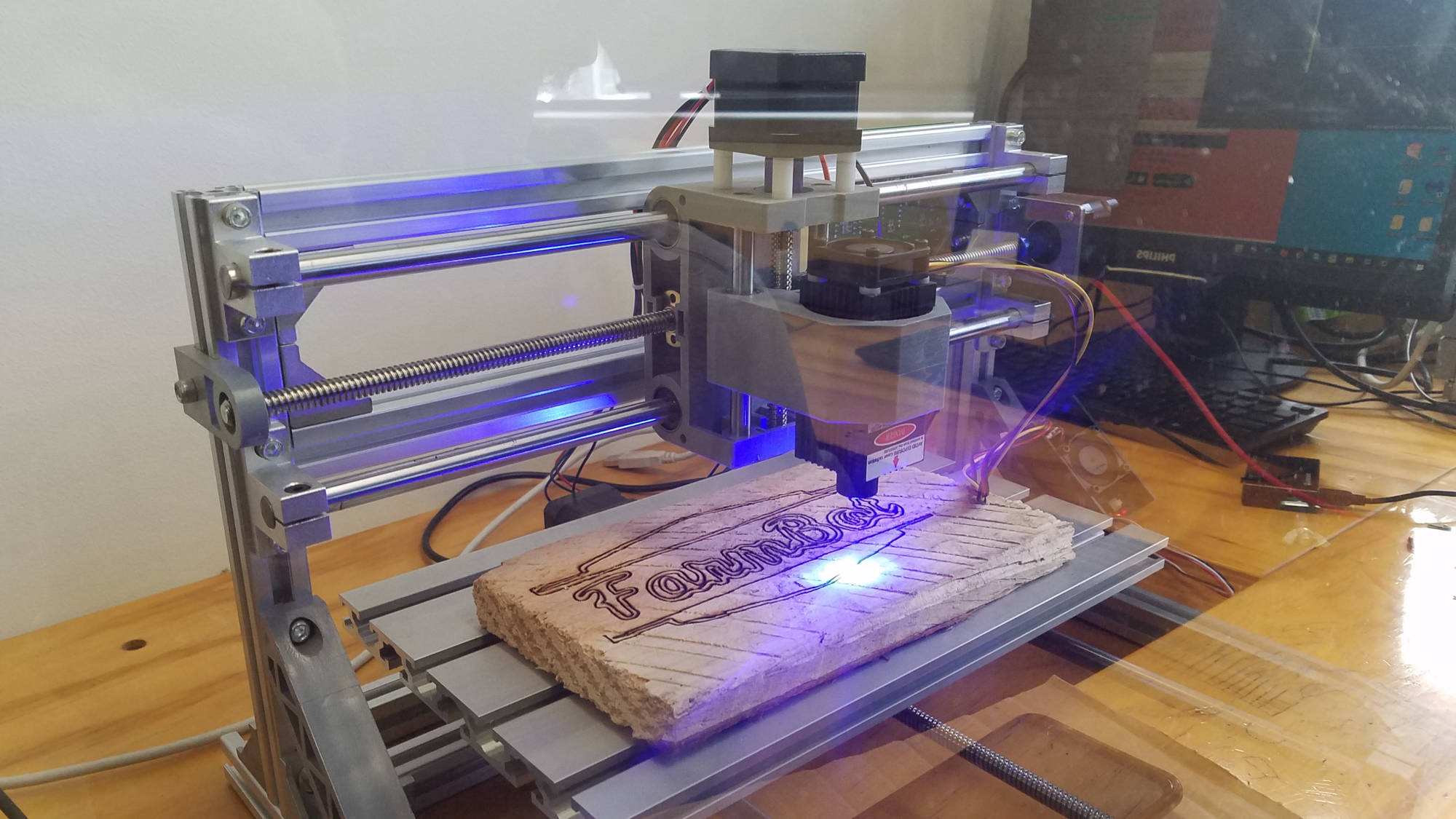

After getting the go ahead from our head of project (Vaughn) to build a Battlebot, we started disassembling 'farmbot' and started coming up with ideas to start our project.

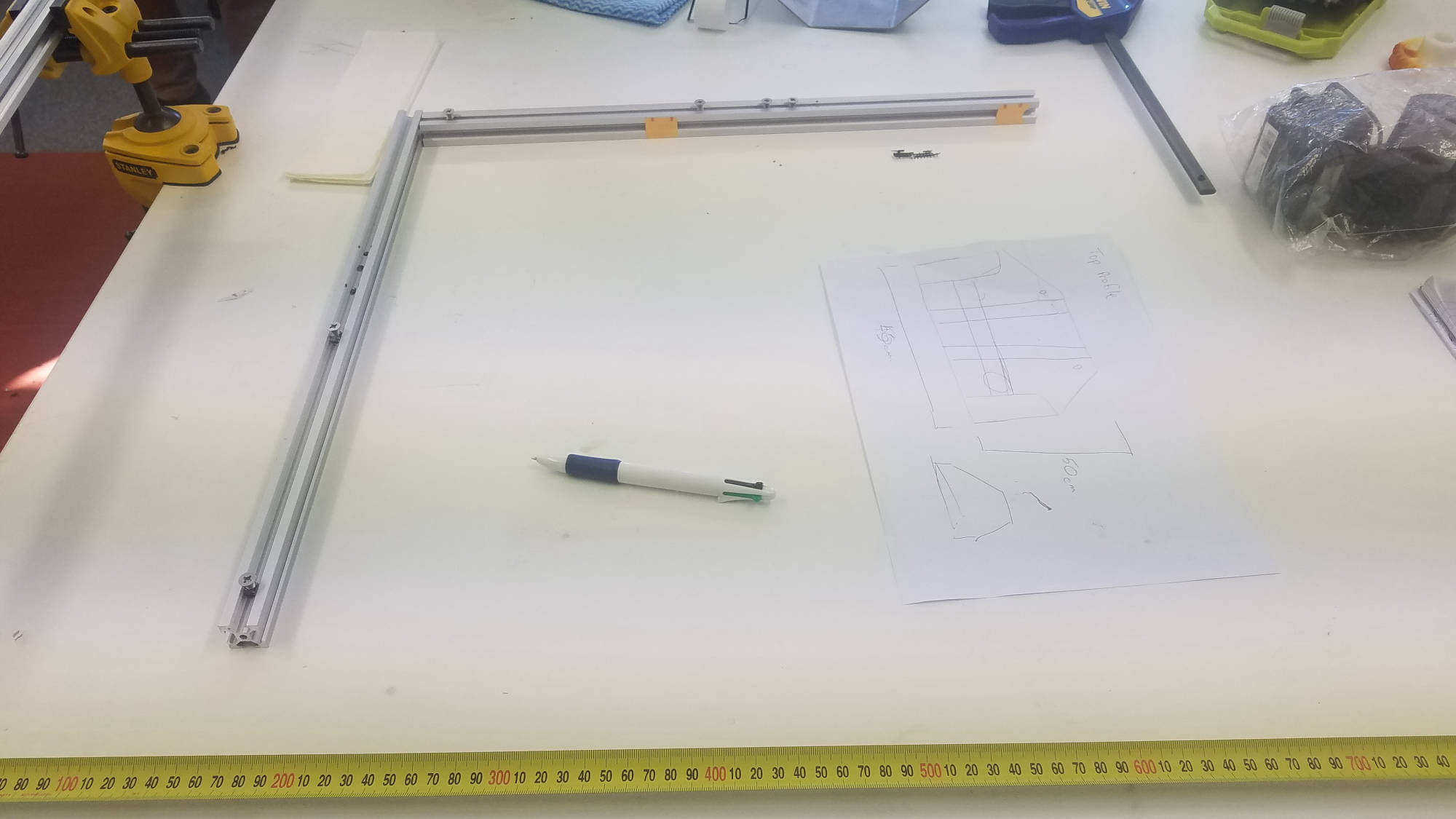

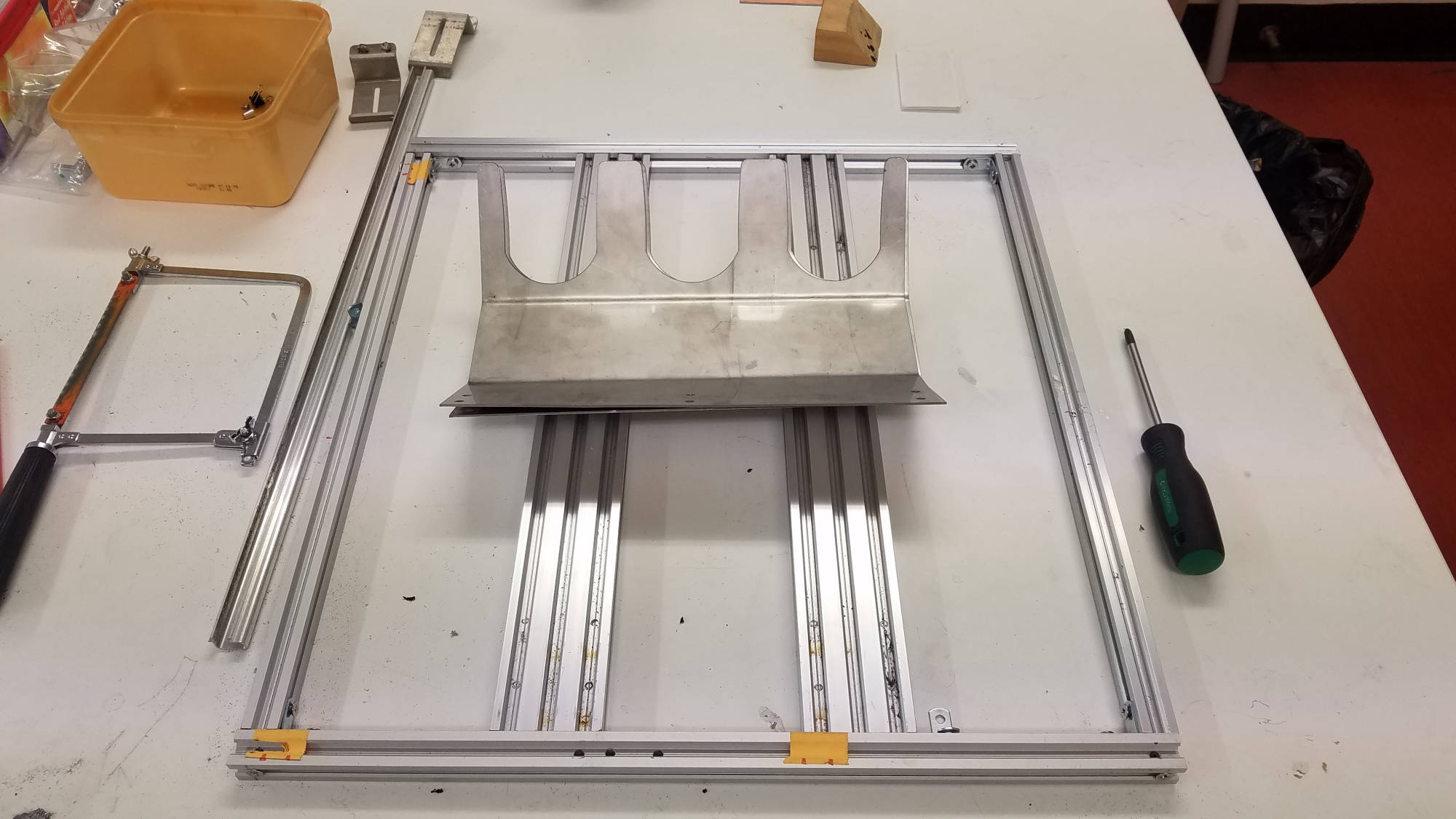

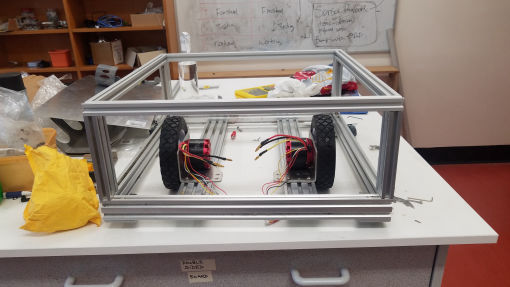

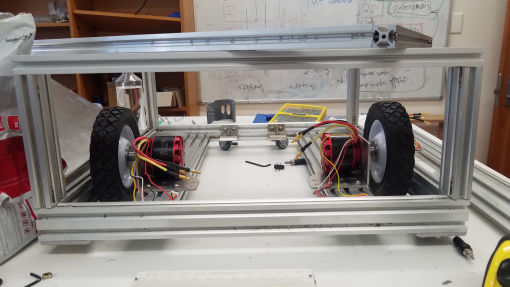

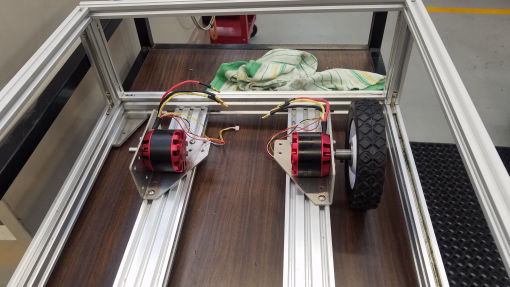

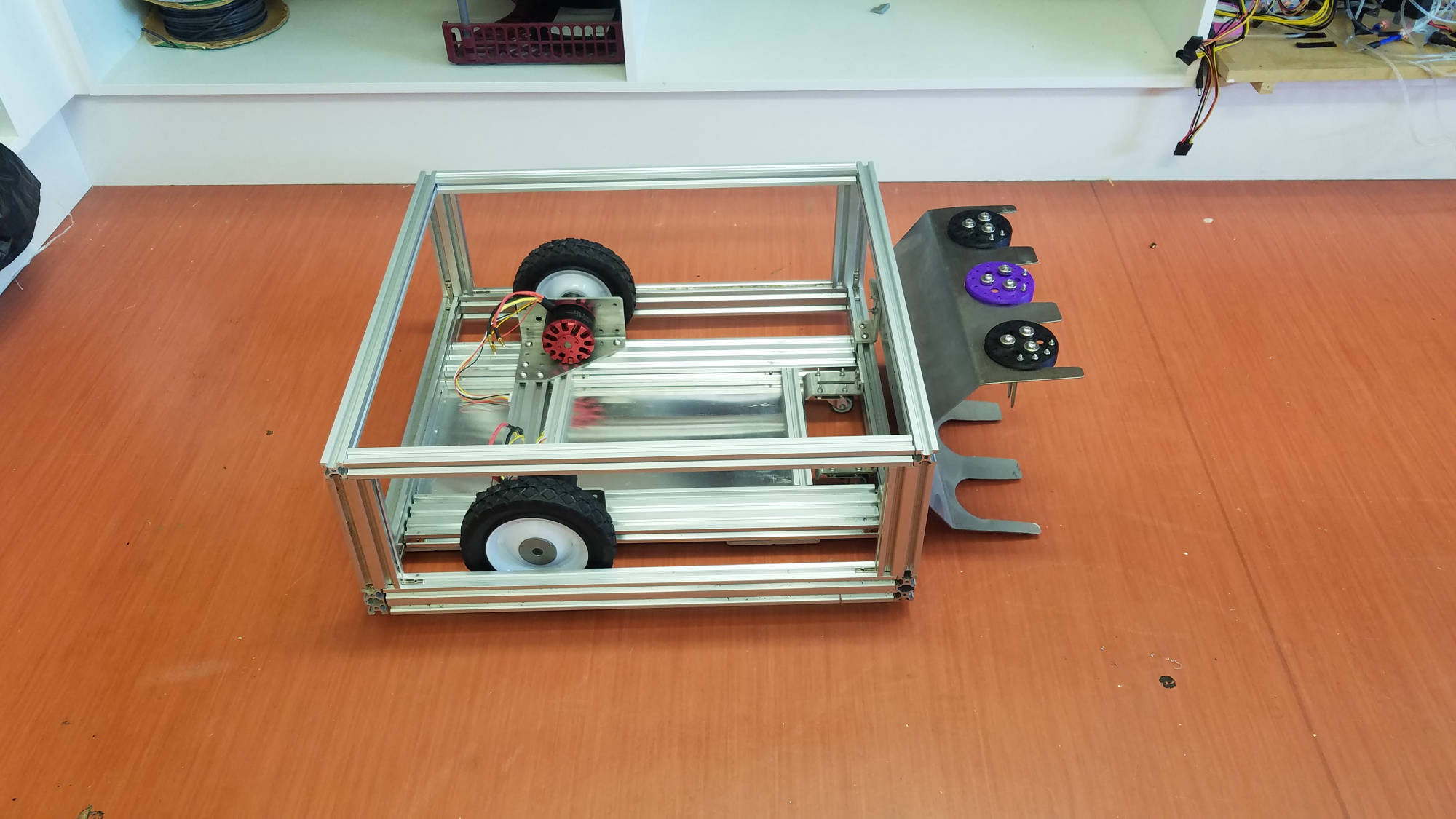

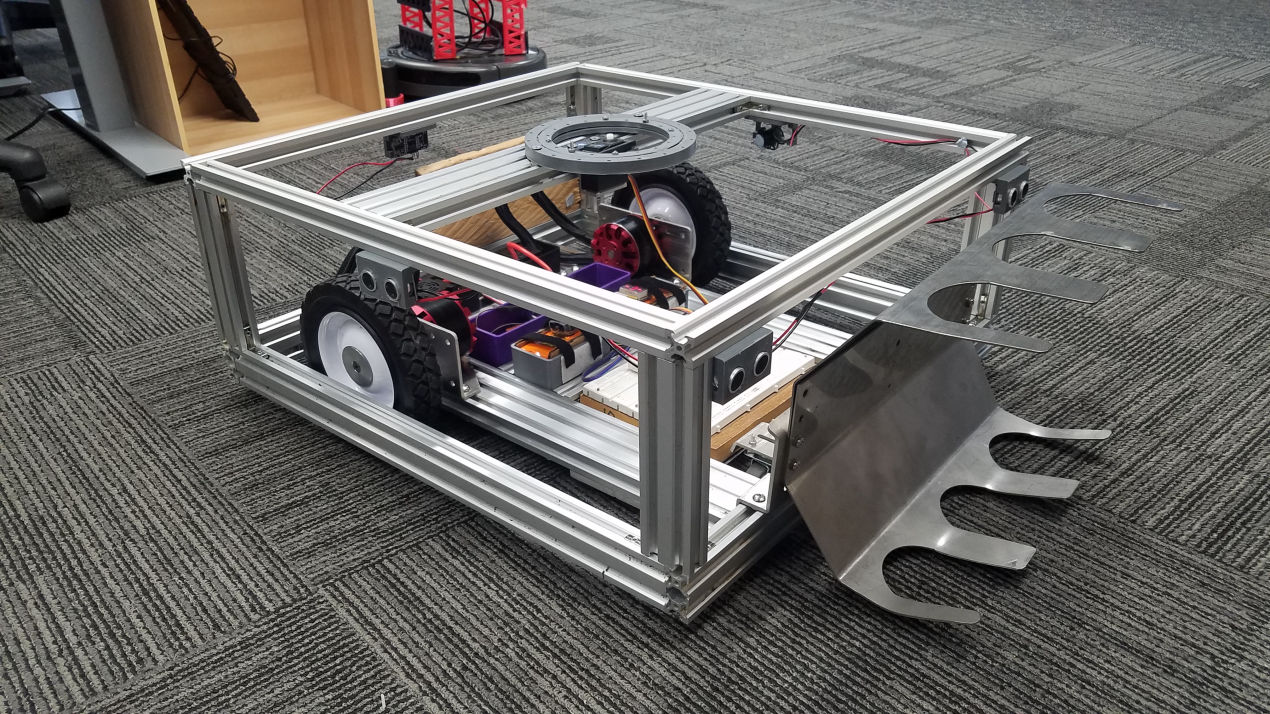

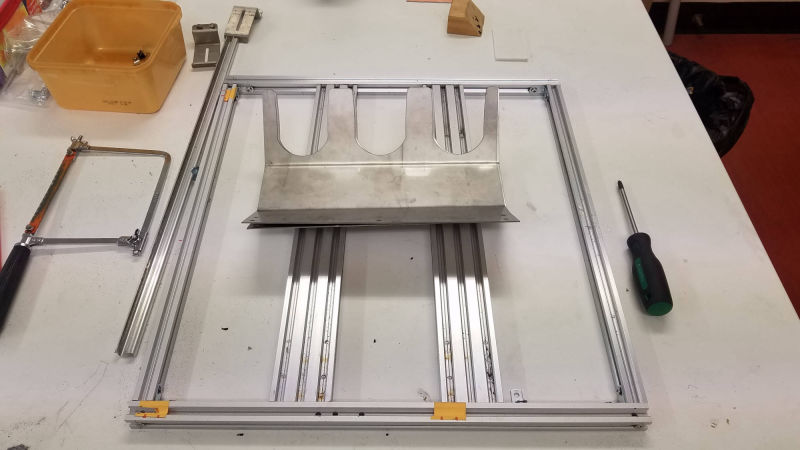

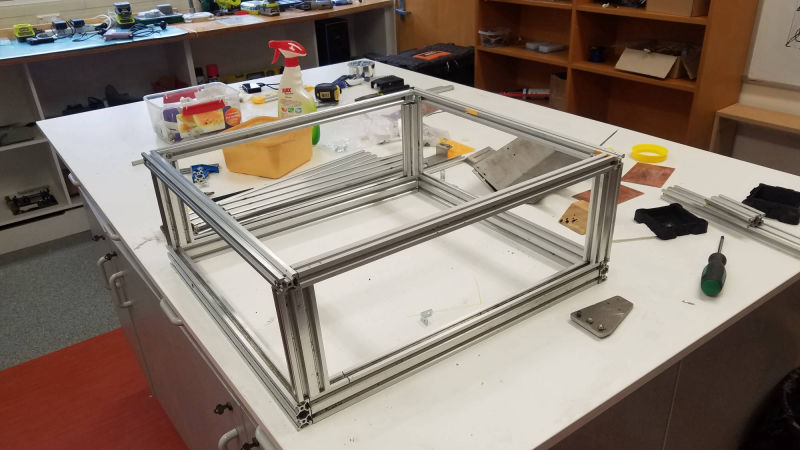

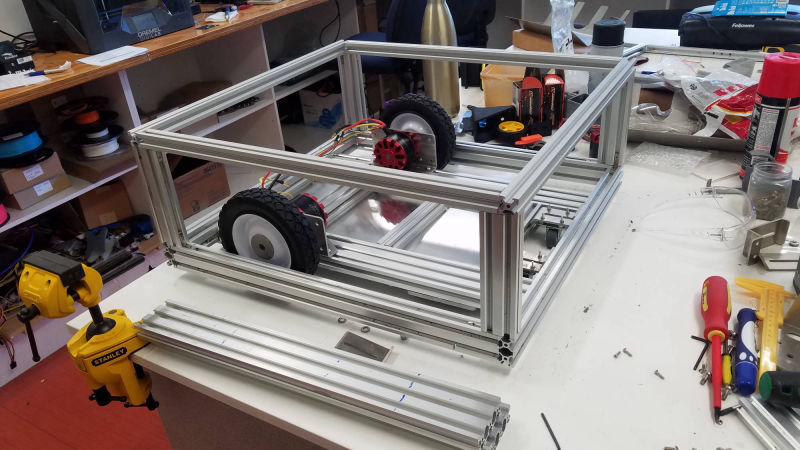

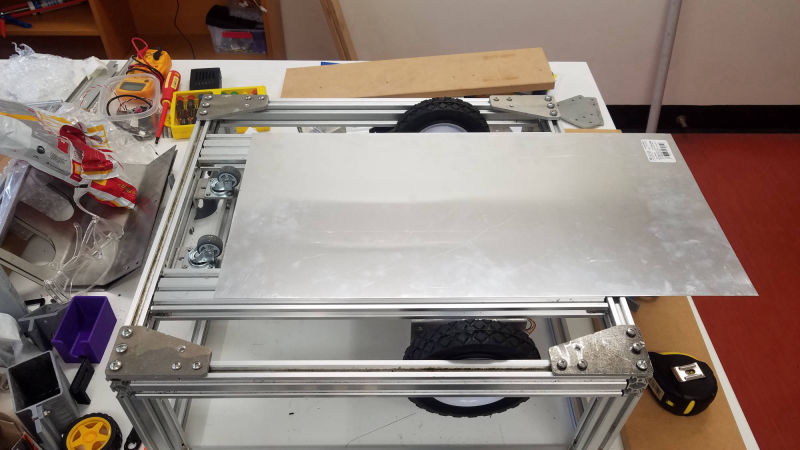

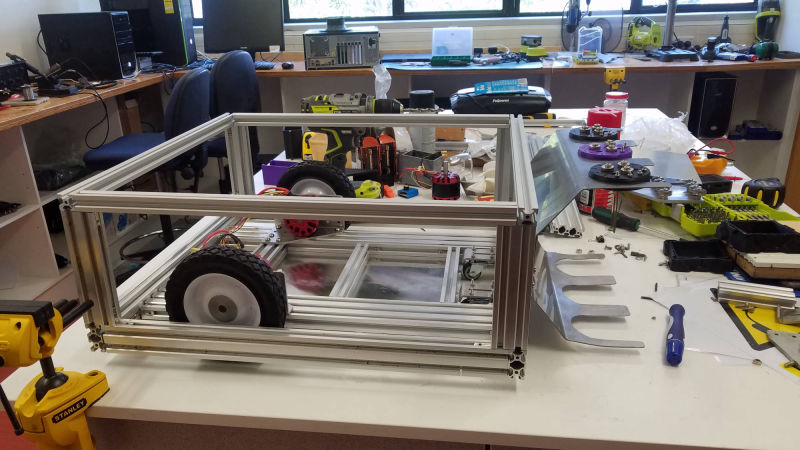

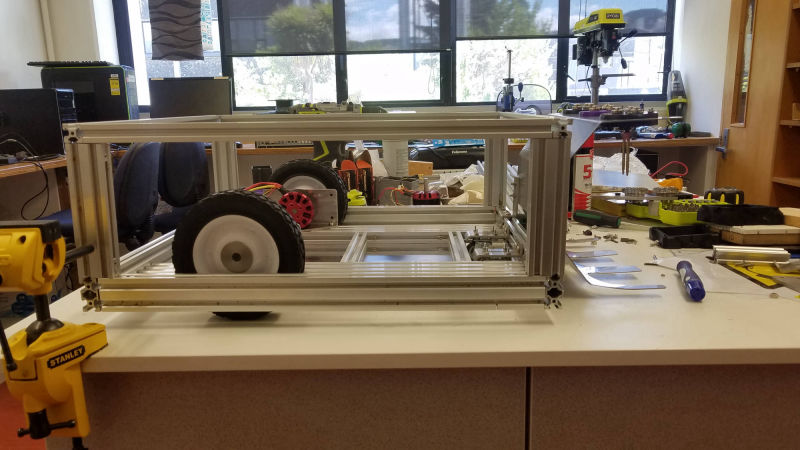

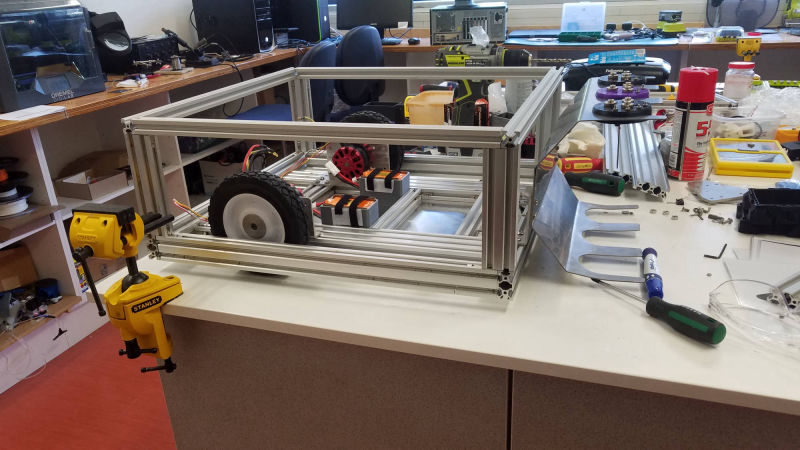

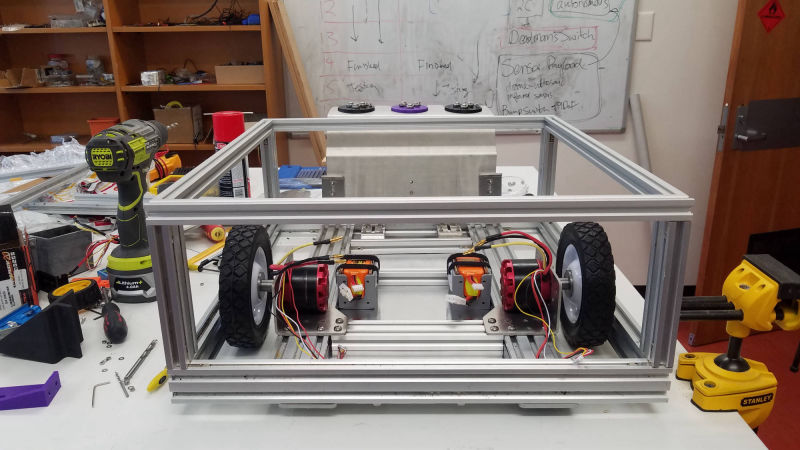

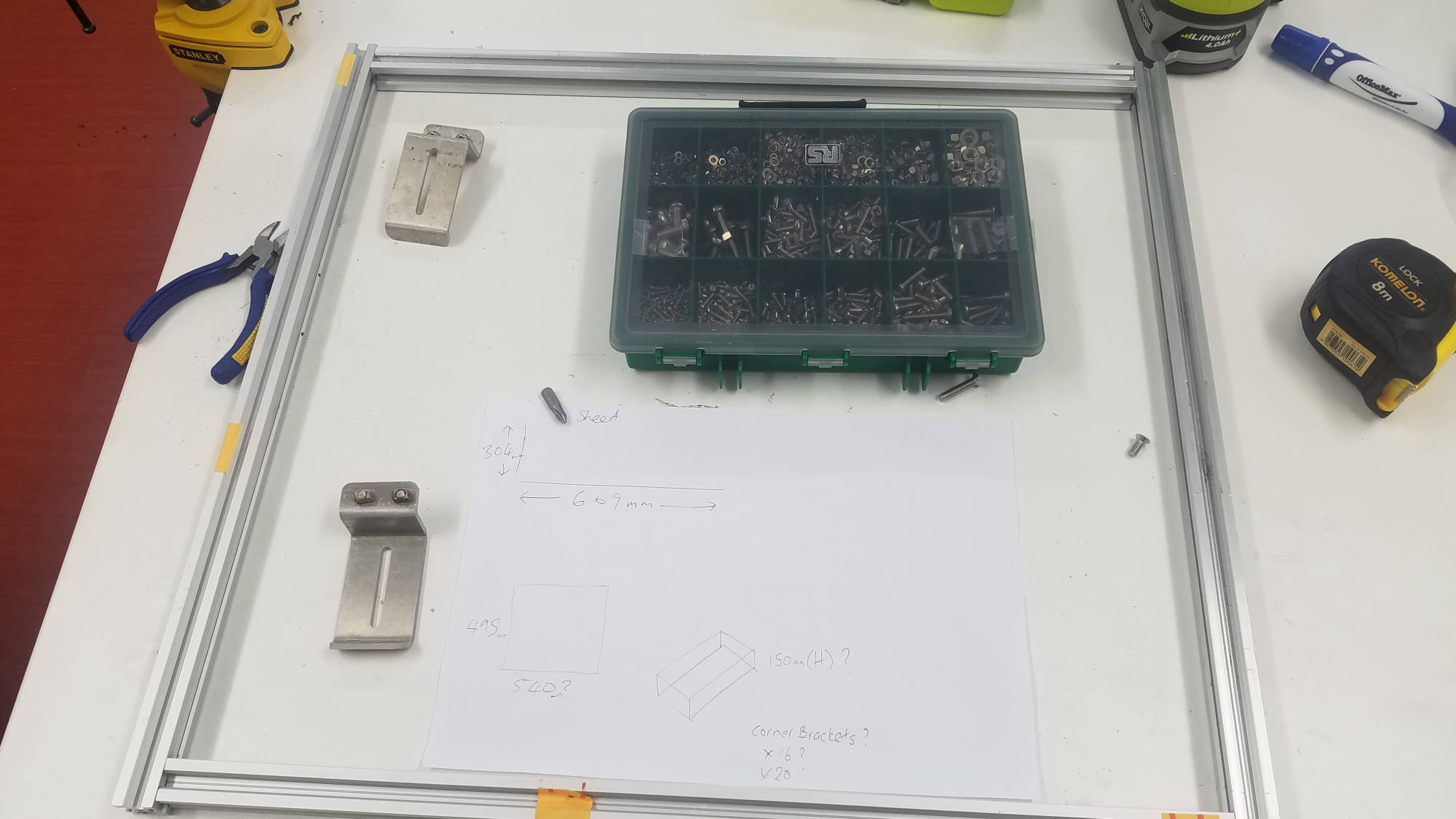

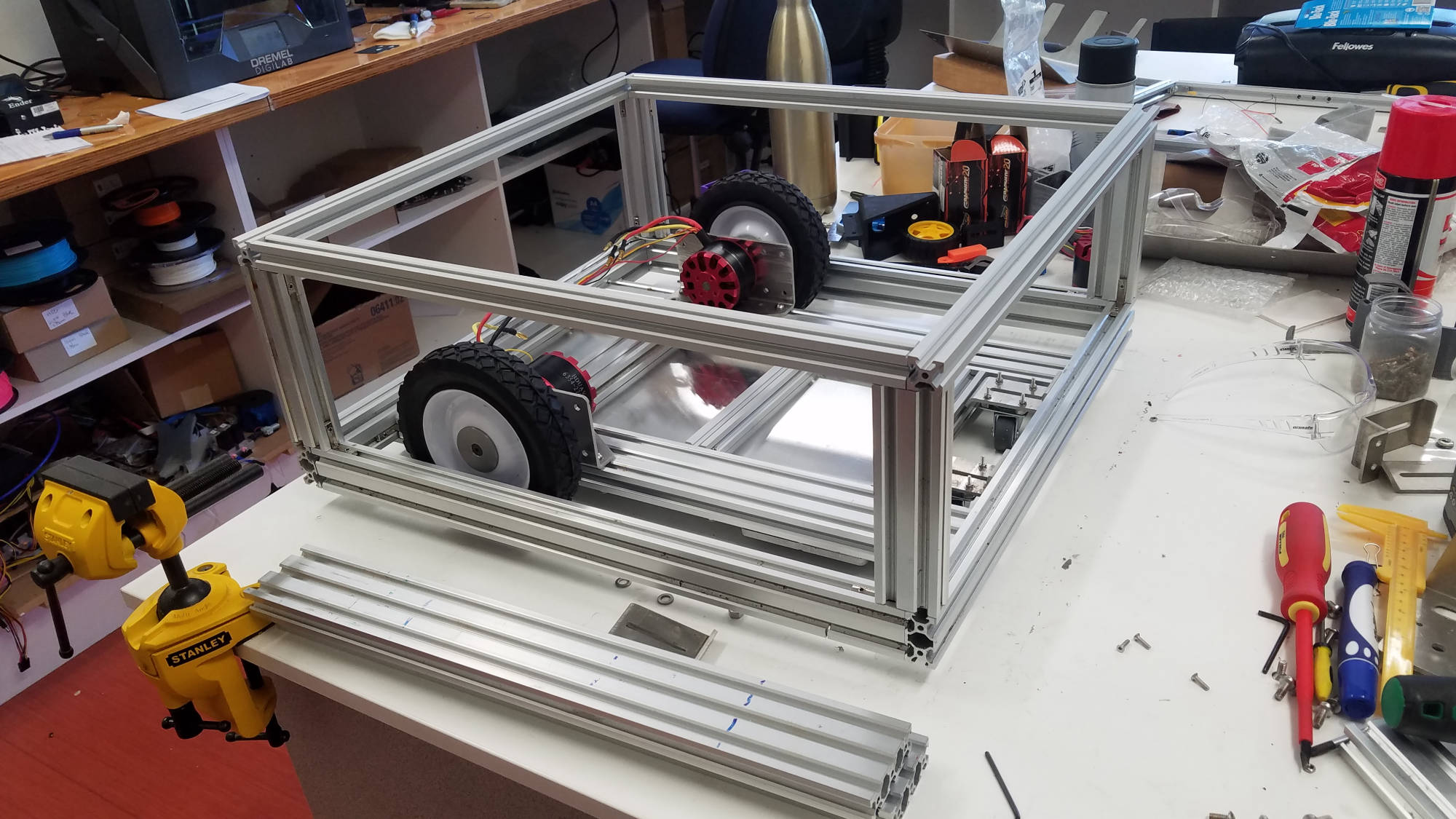

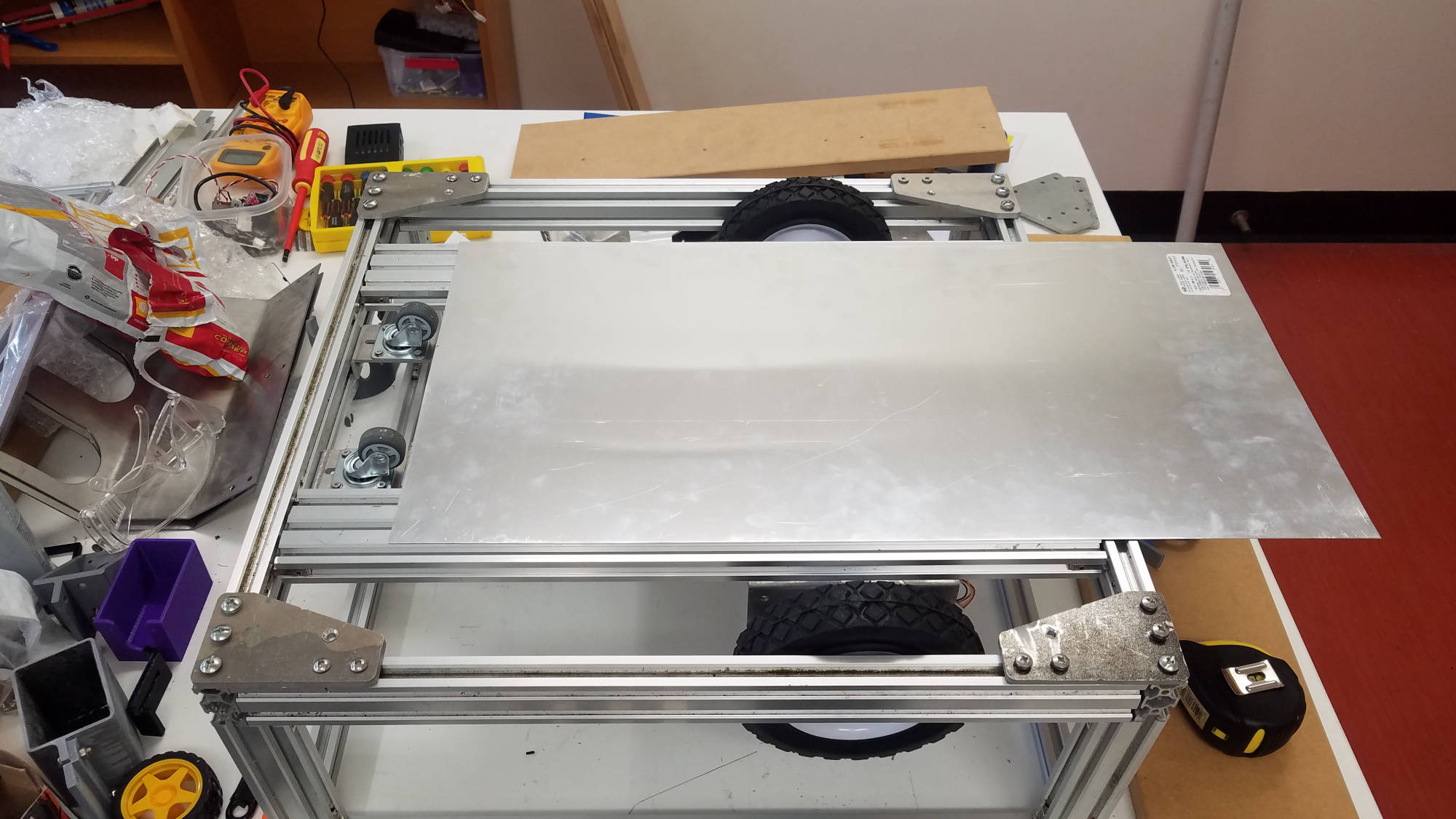

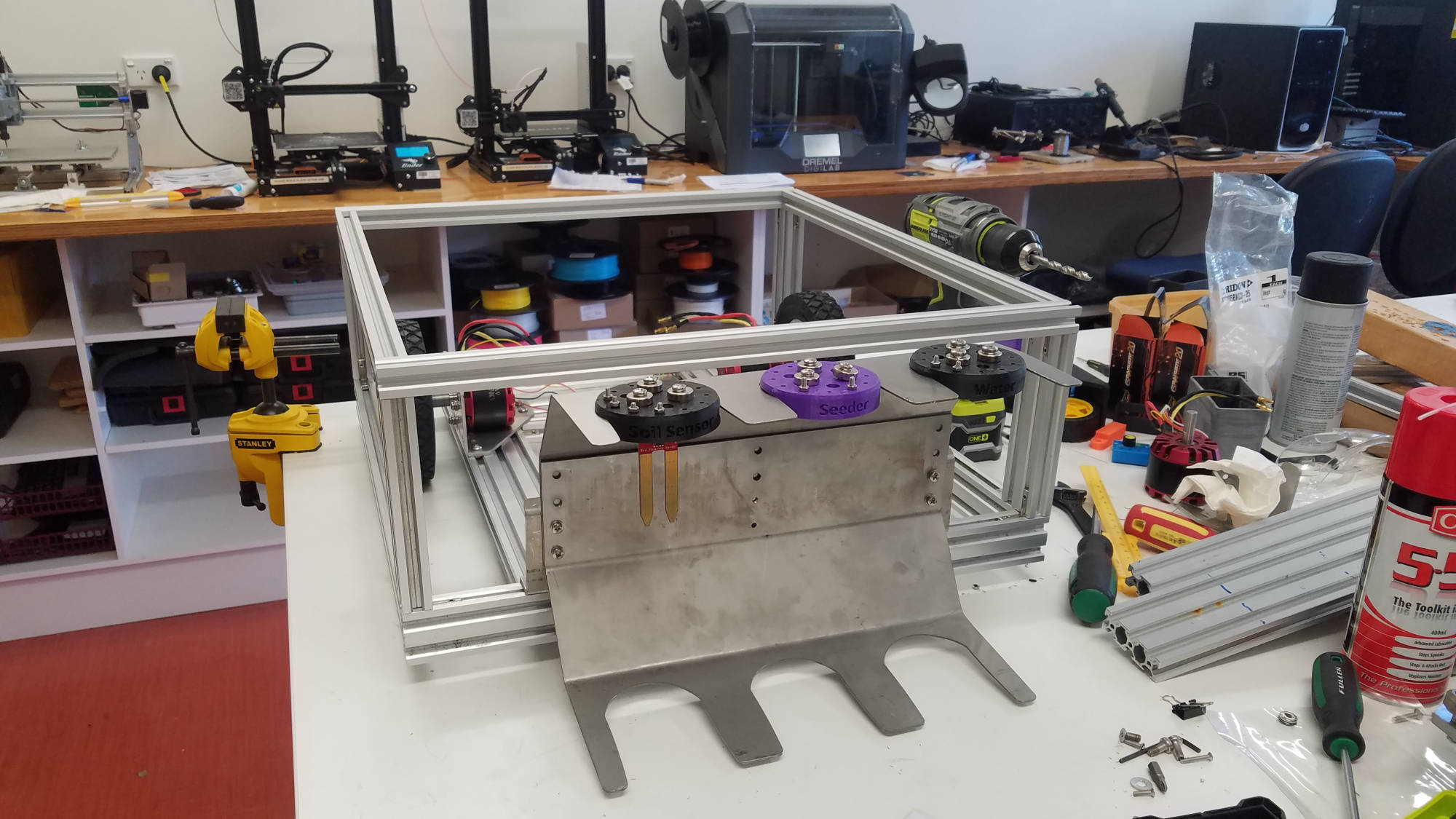

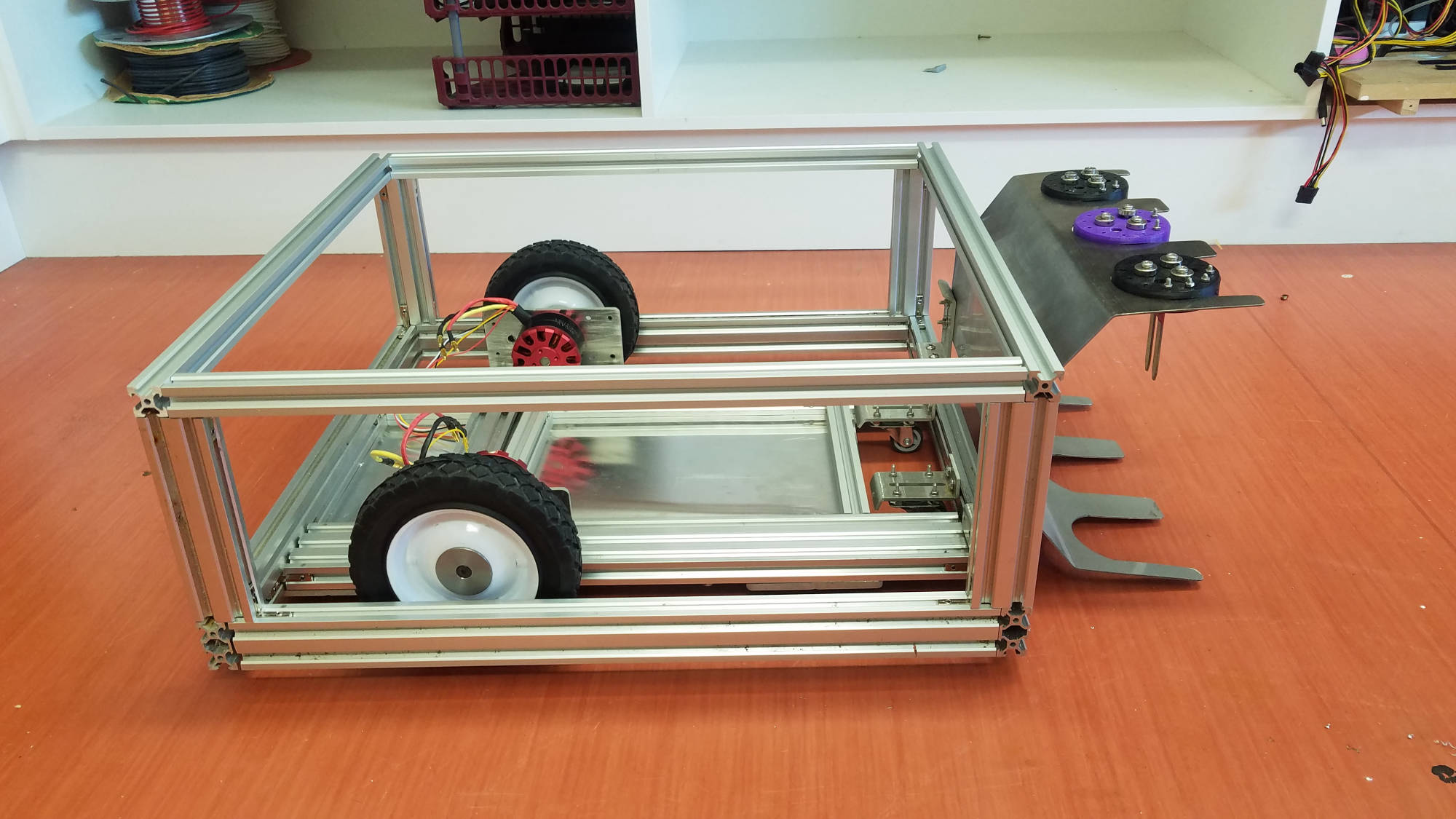

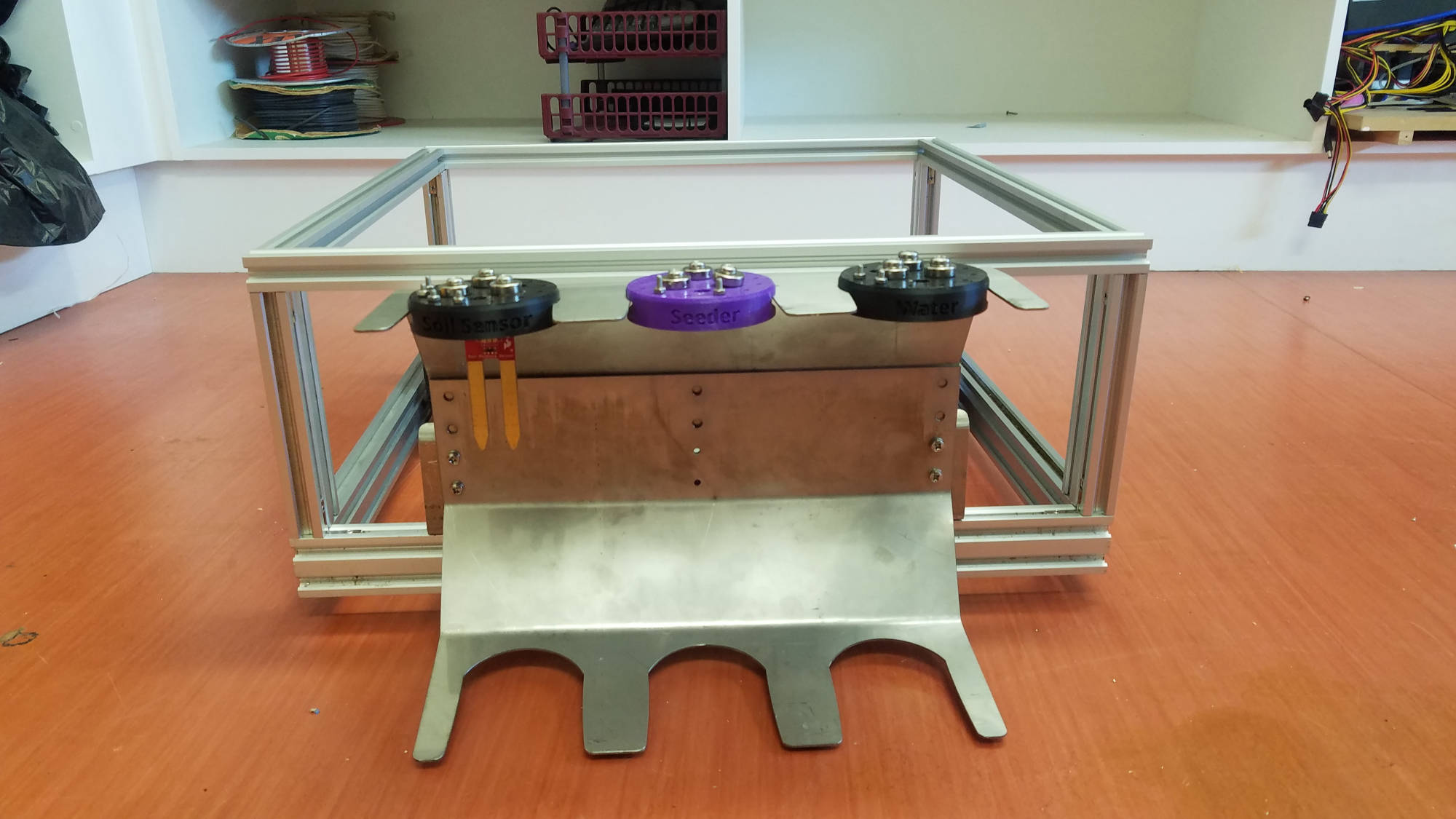

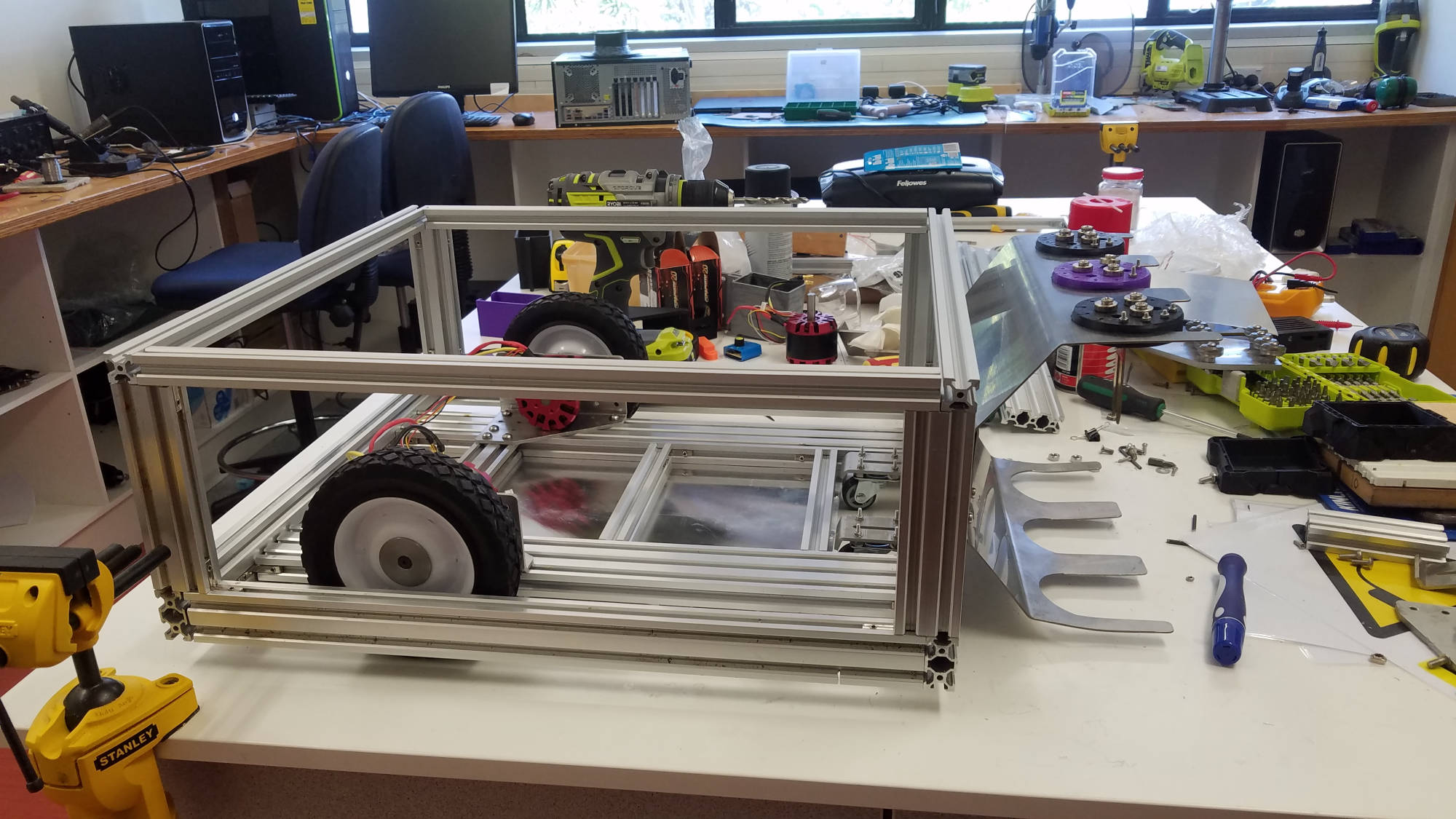

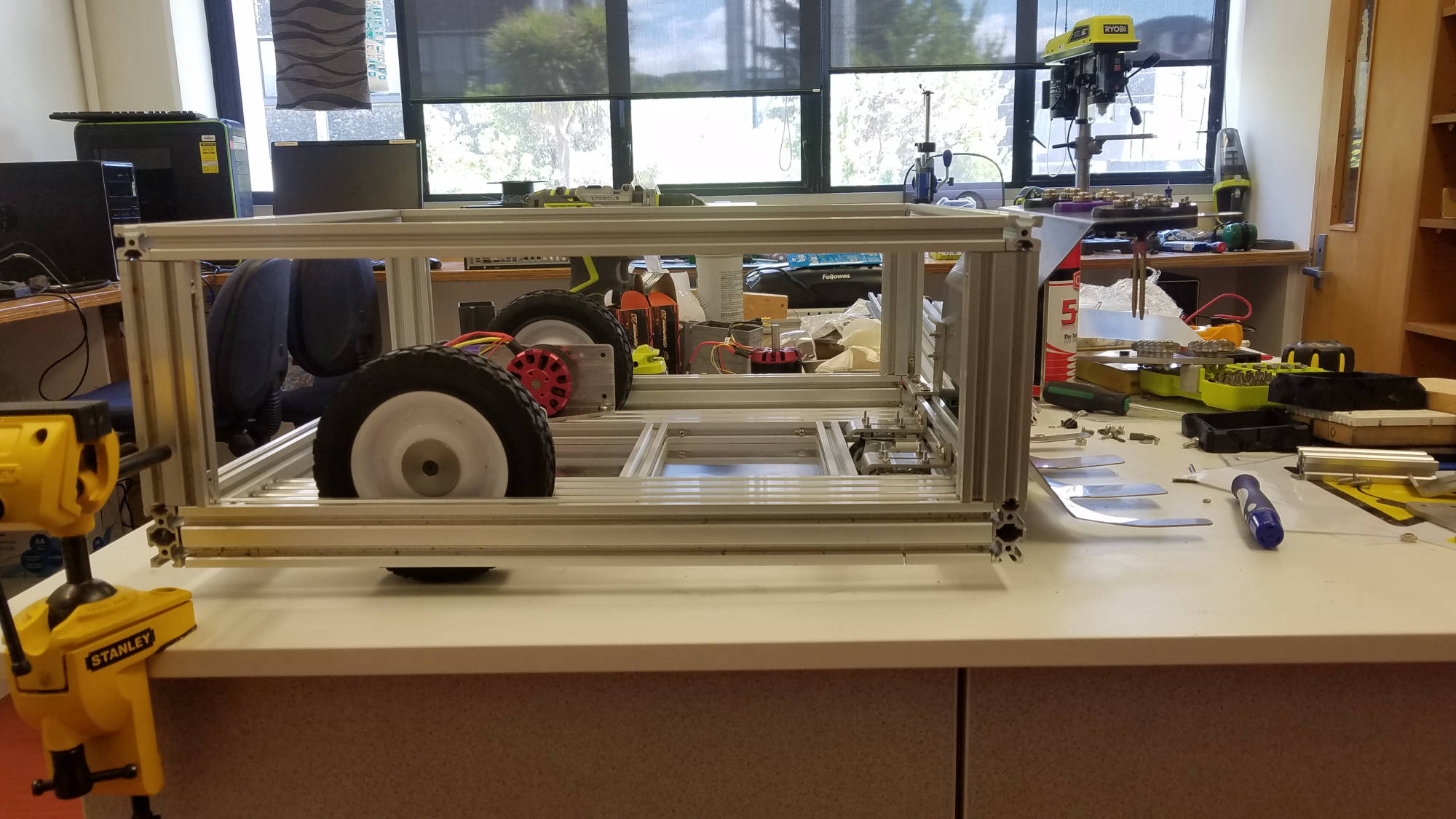

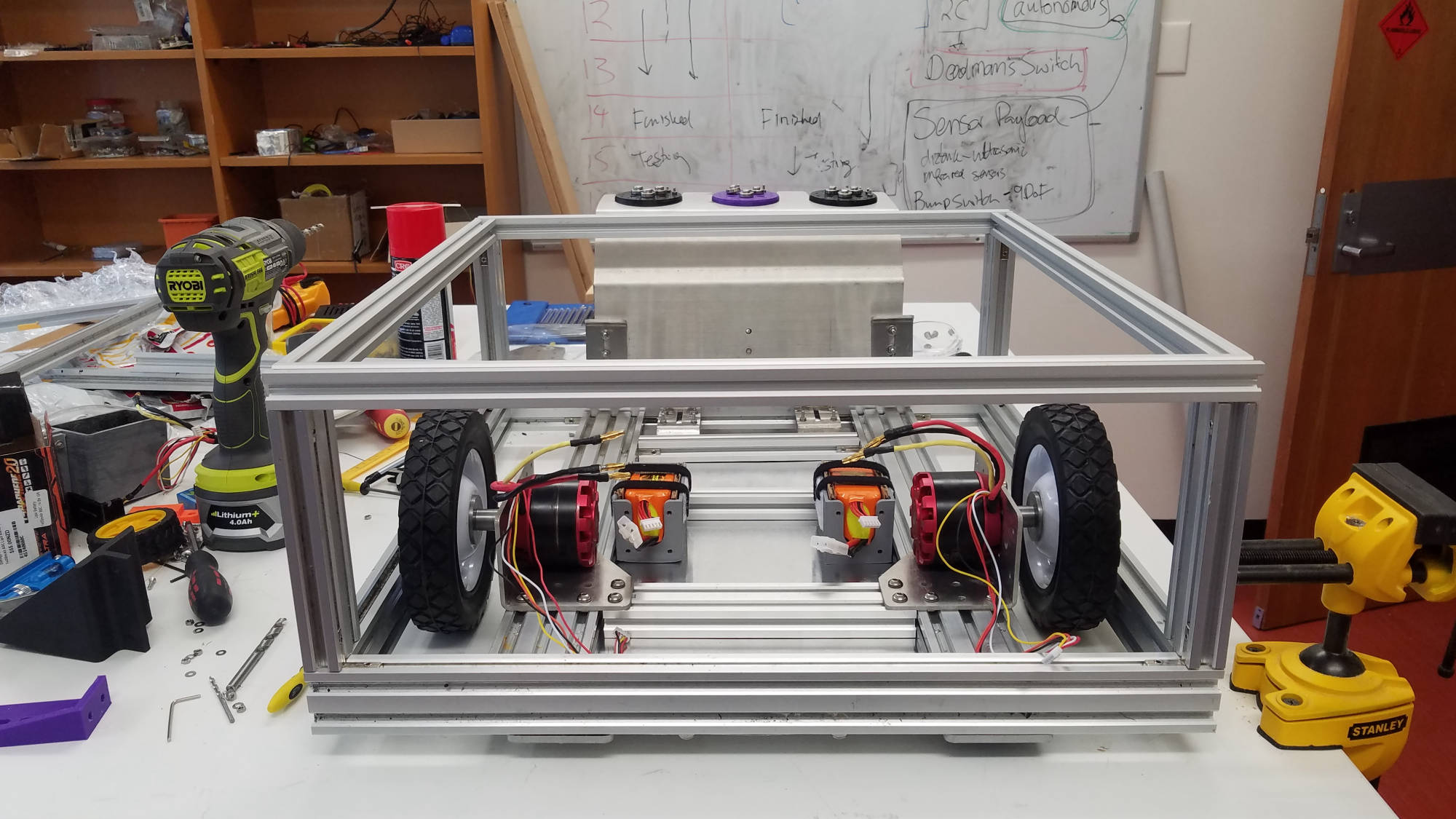

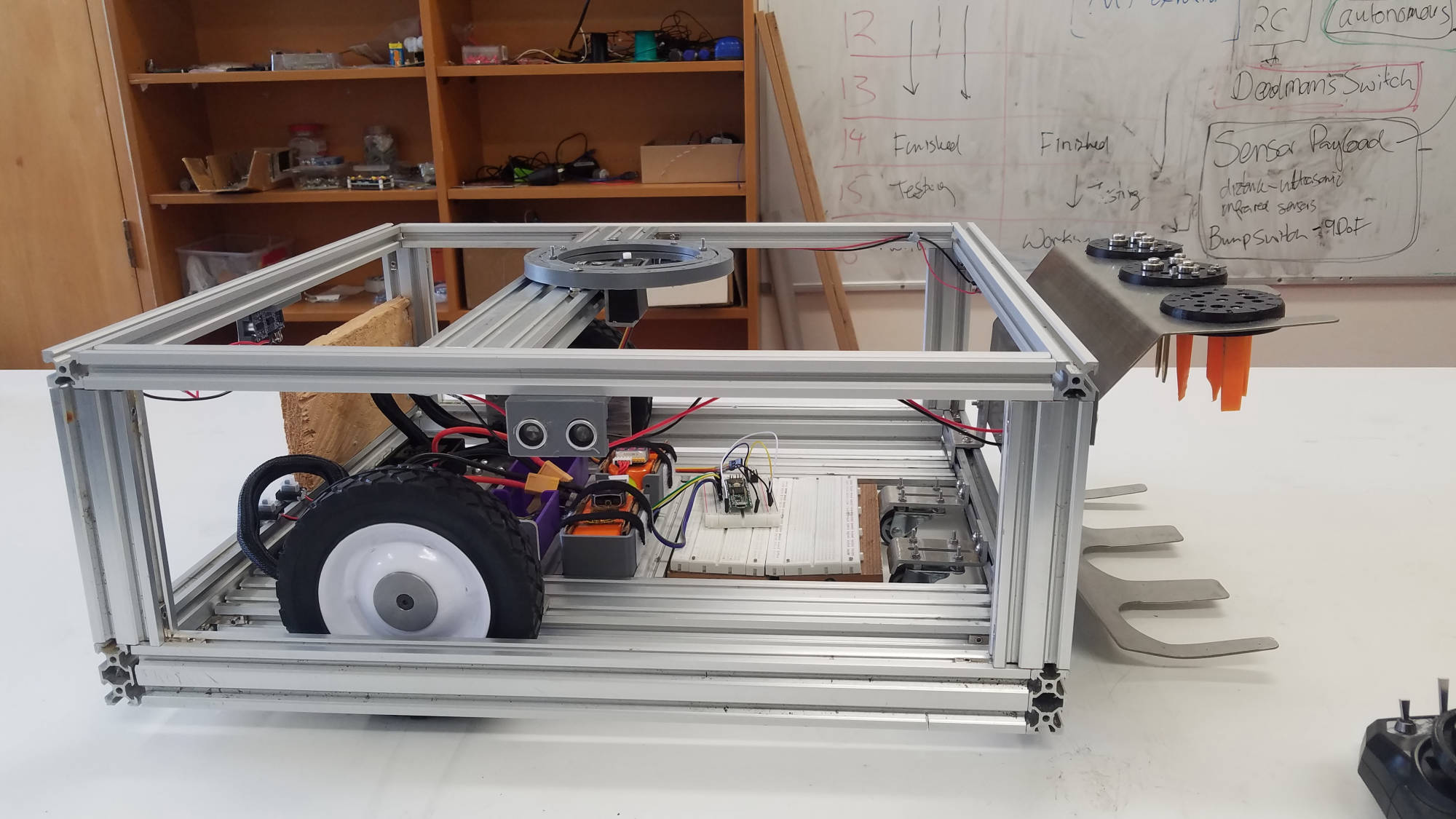

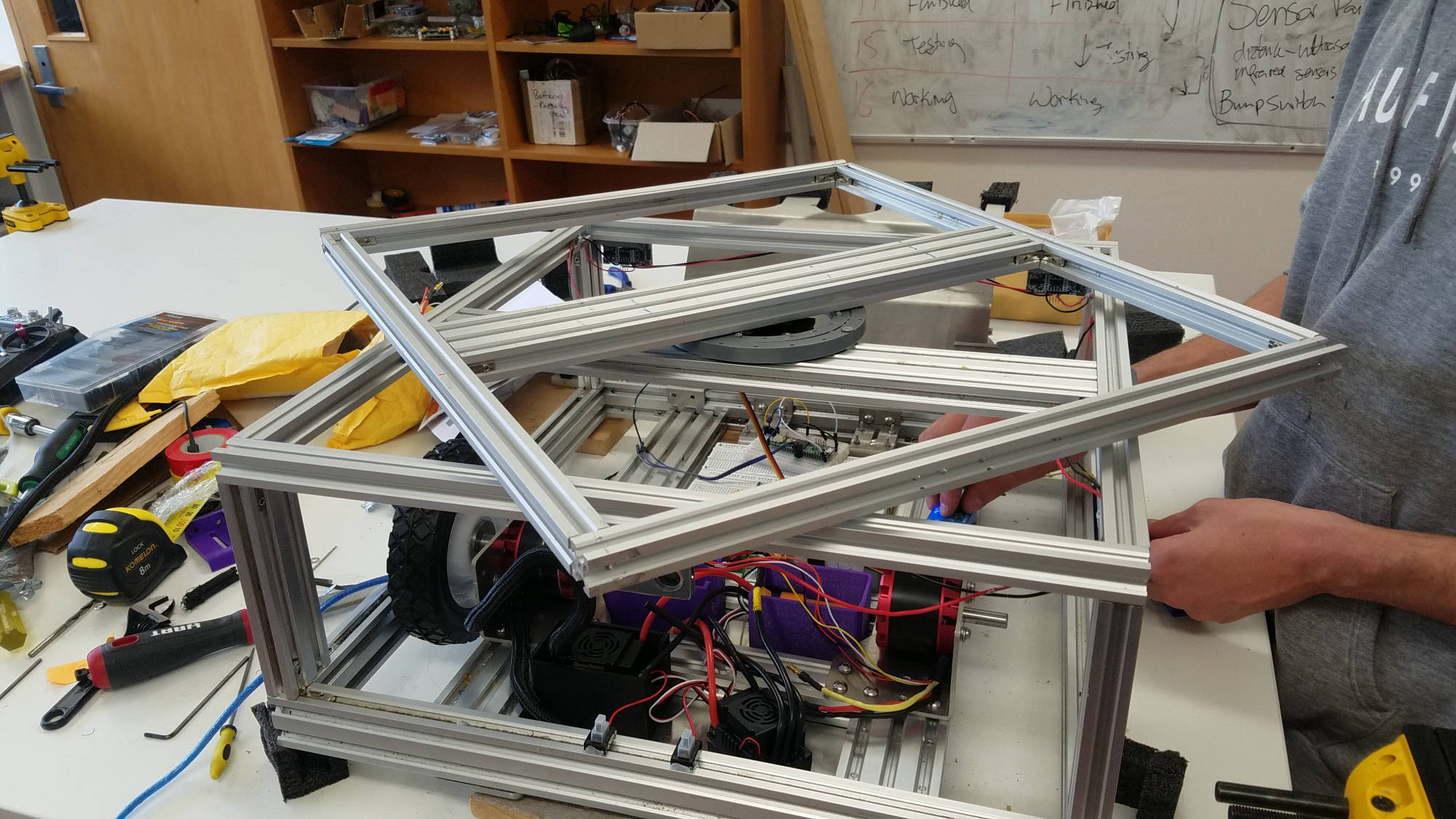

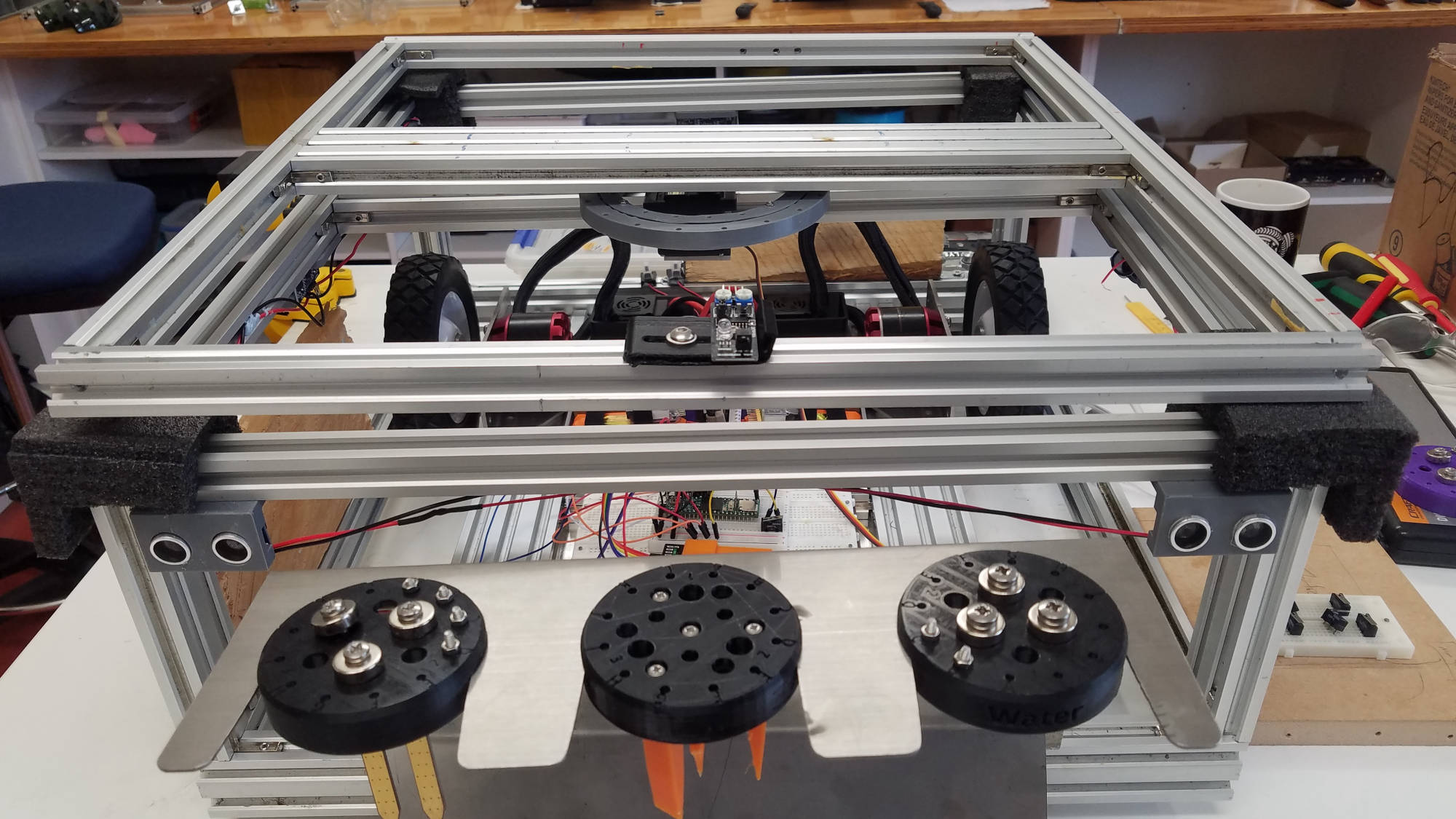

Redisigning Farmbot into a battle robot meant deciding what we can recycle from that project to get us rolling. We had a lot of Aluminium framing and brackets to begin with.

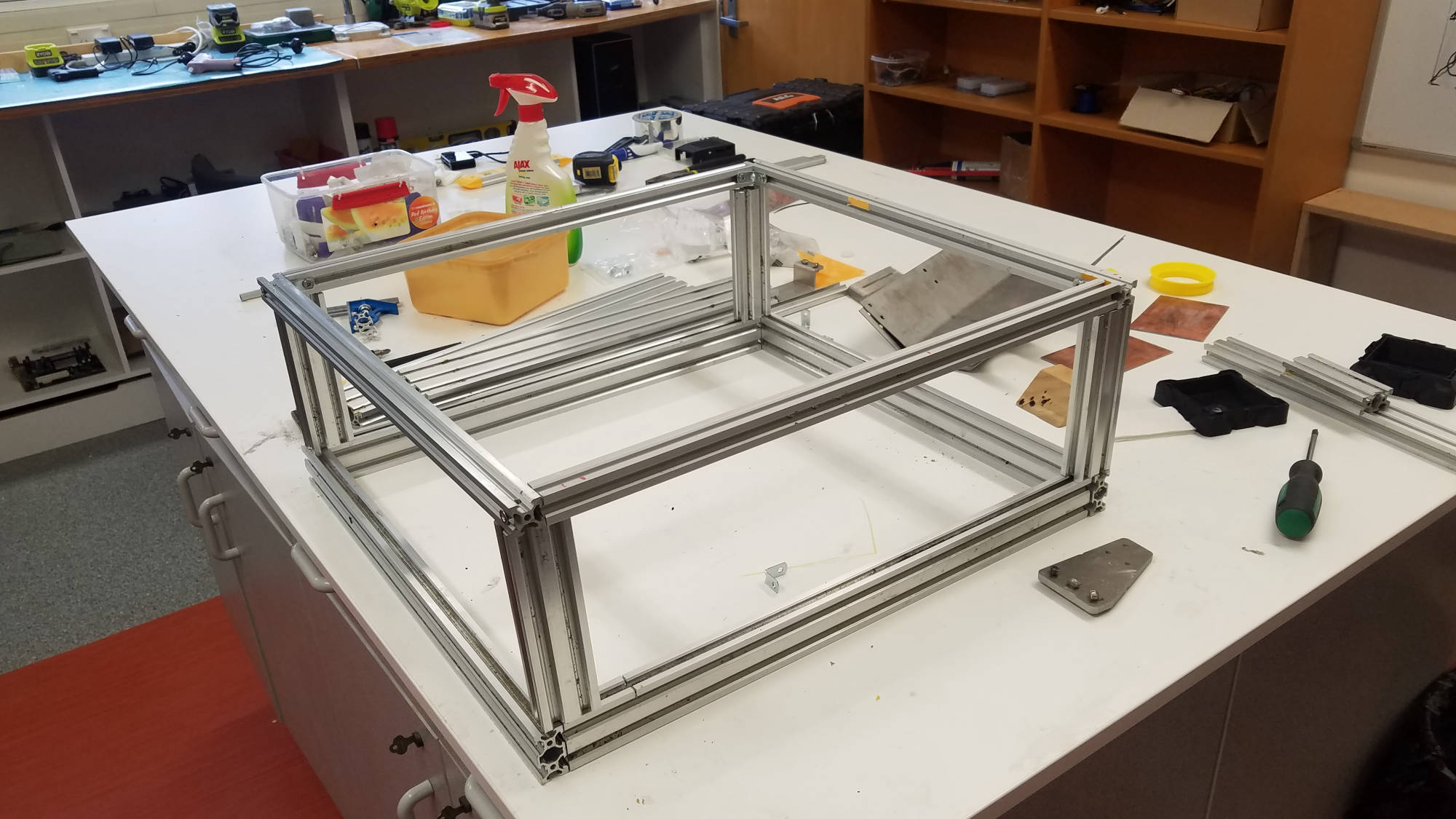

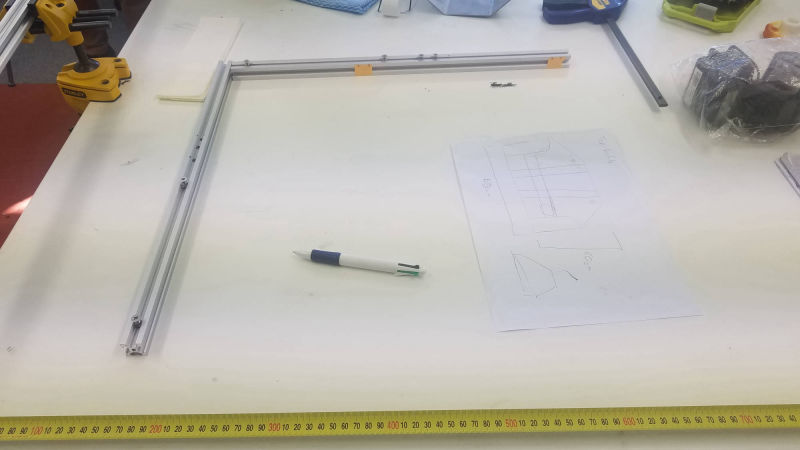

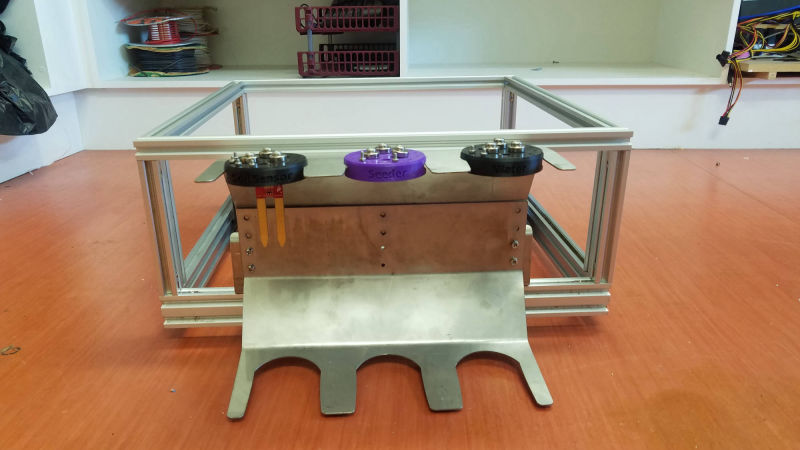

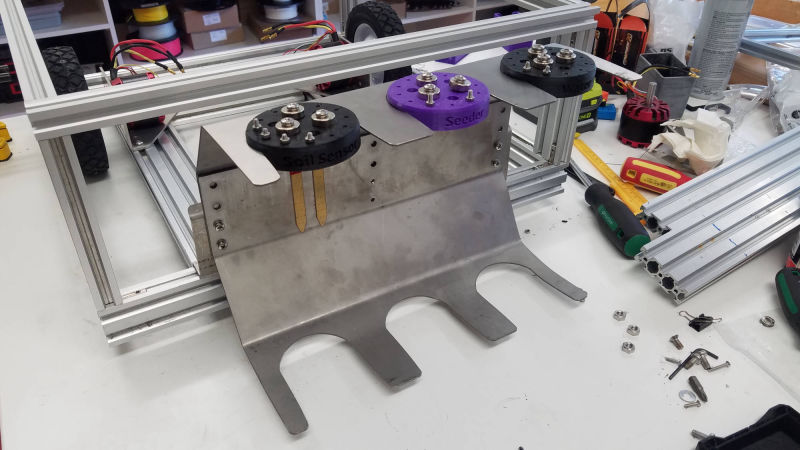

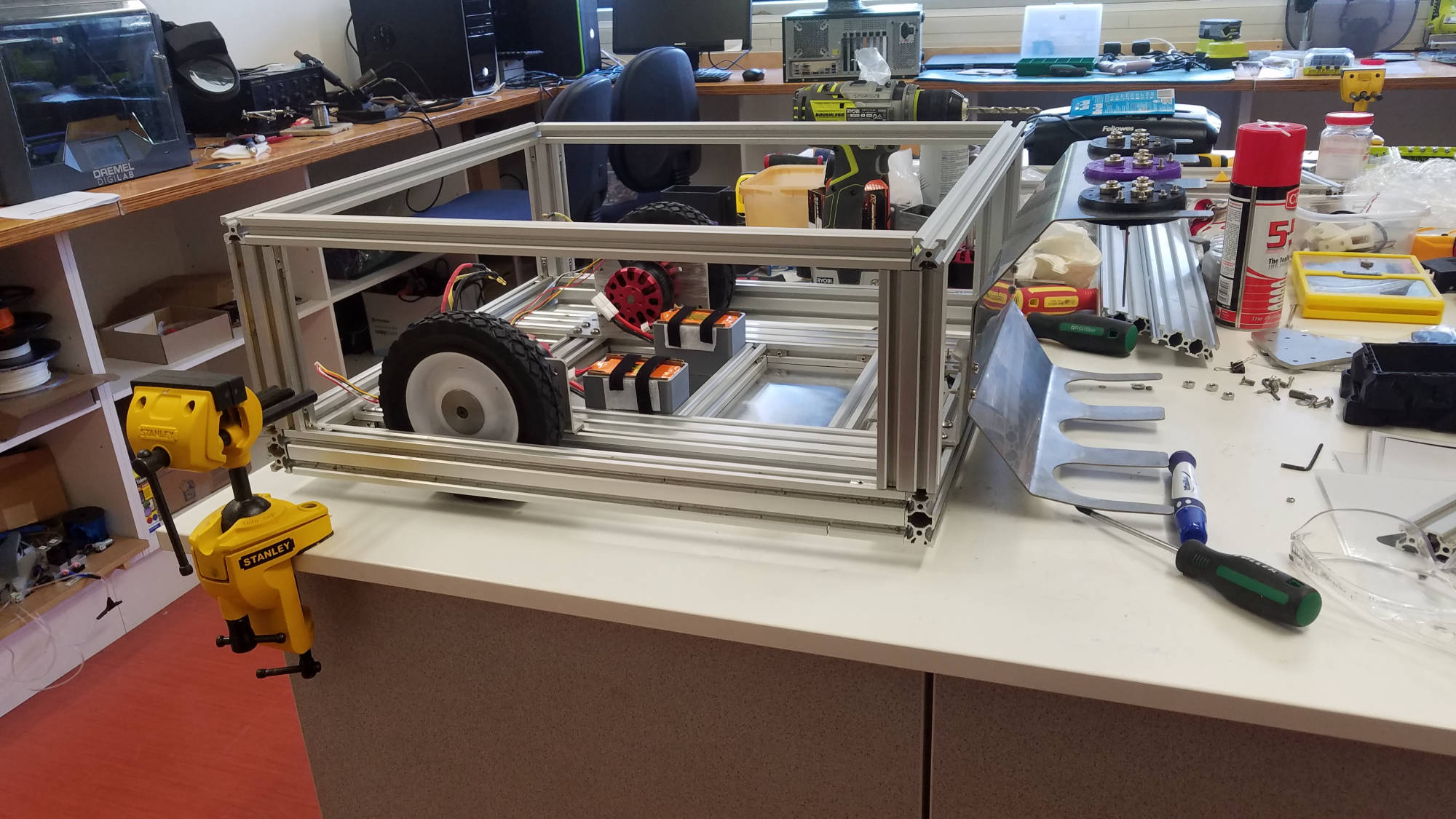

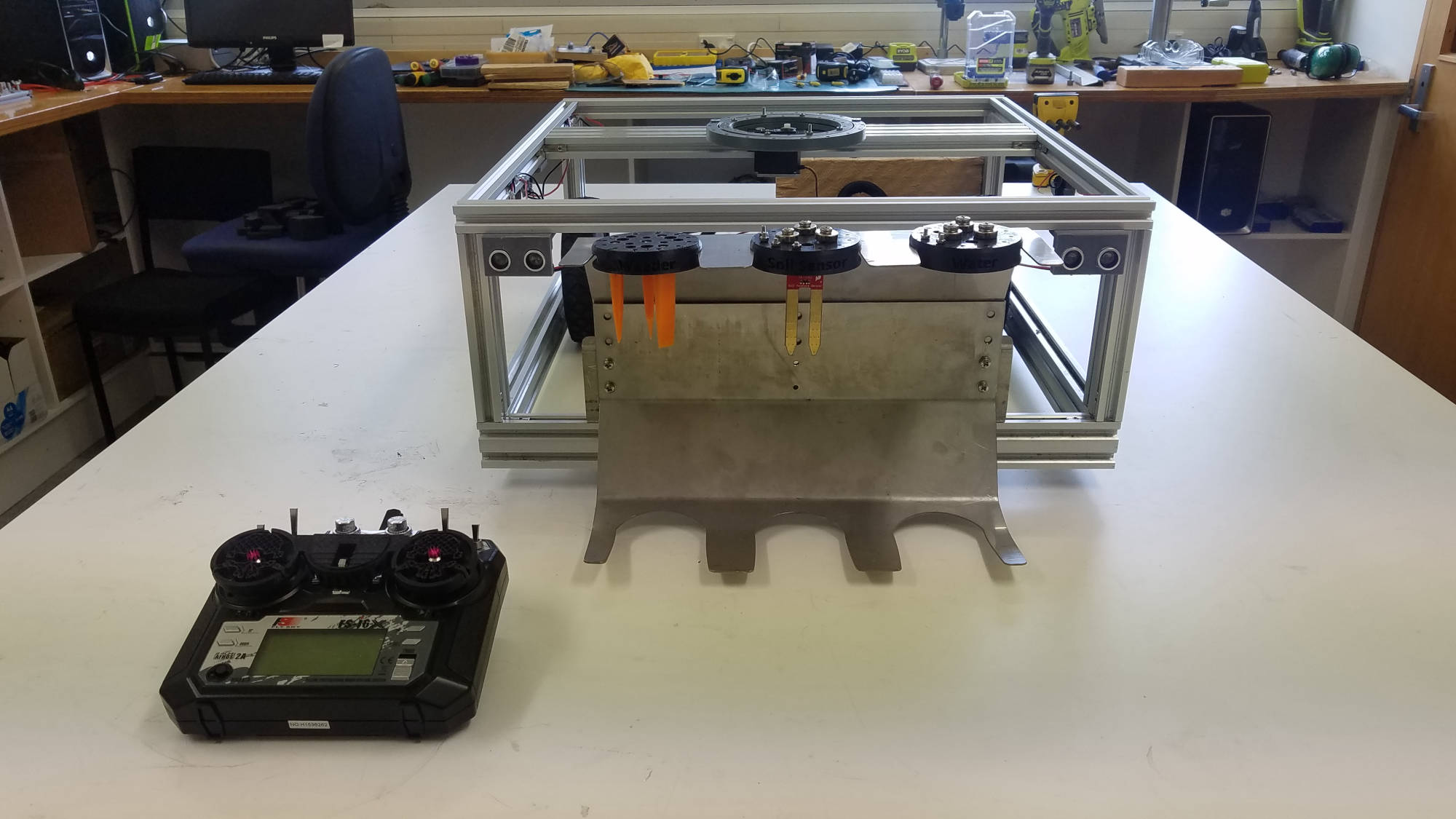

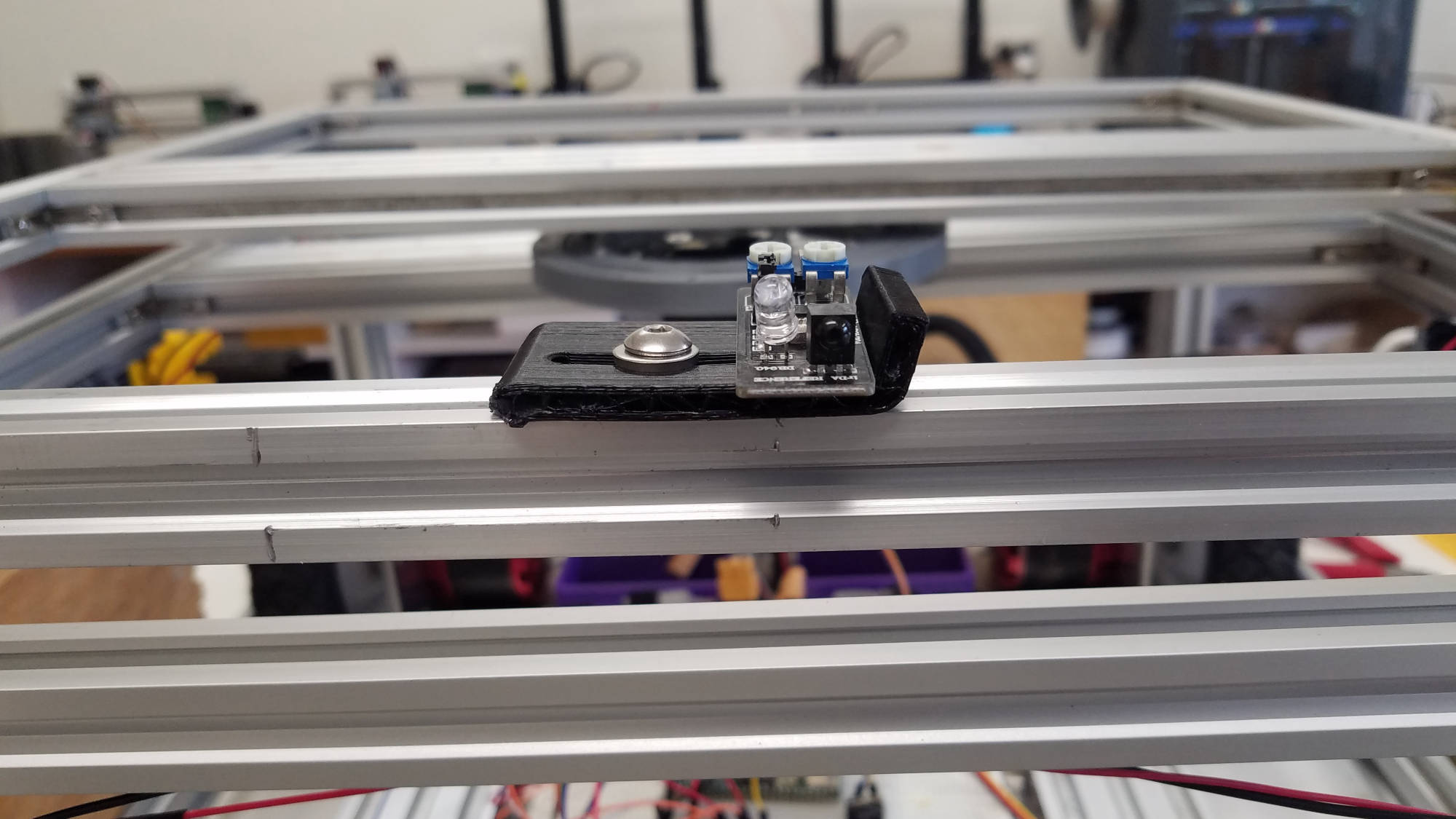

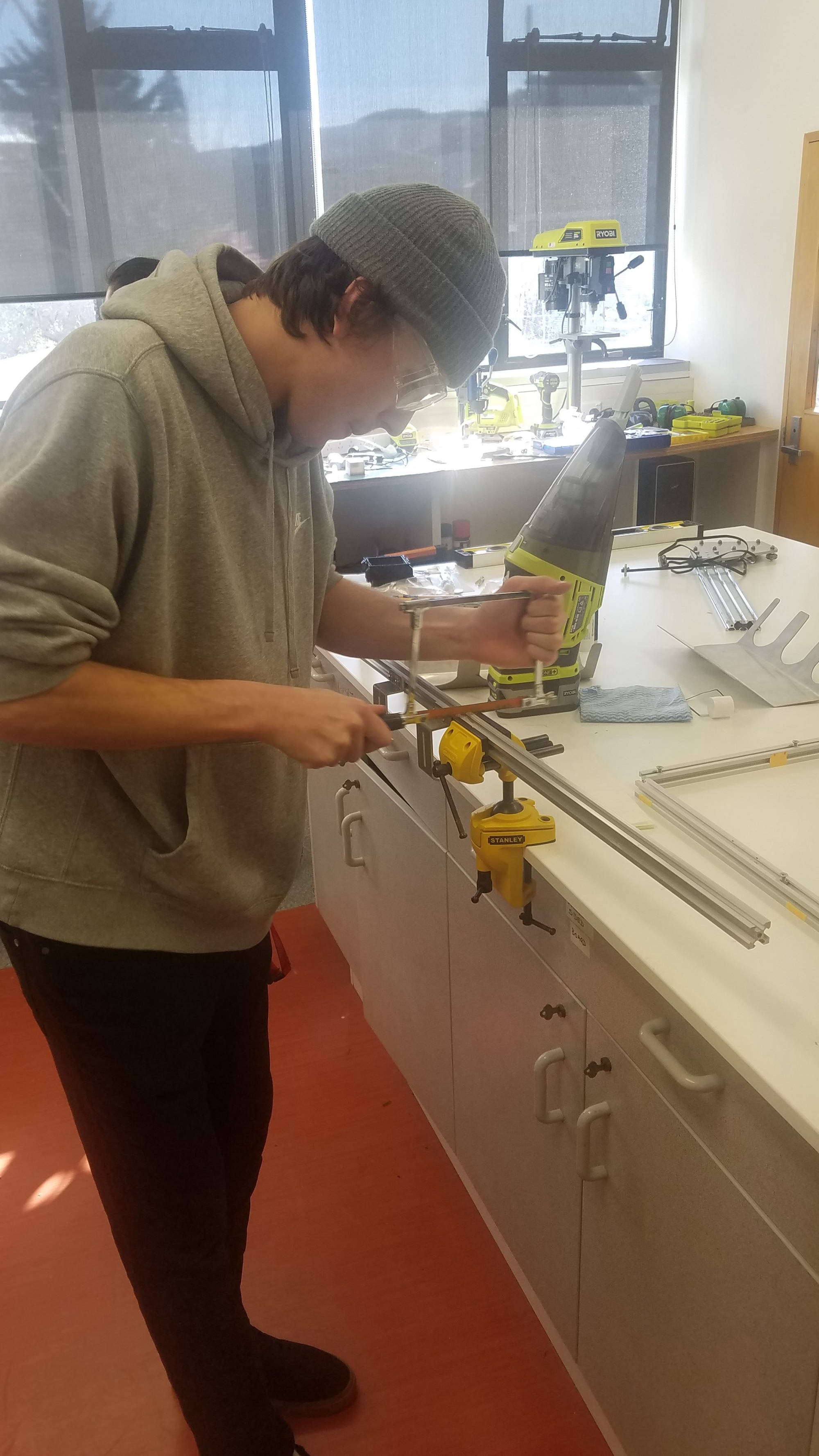

Alluminium extrusion (2020v) was used to start our chassis. We all decided that if we were to do this properly we would need extra resources like machinery and other tools to get this chassis built.

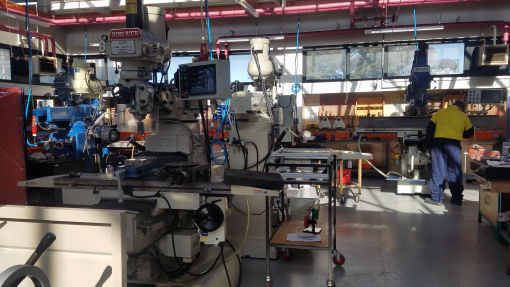

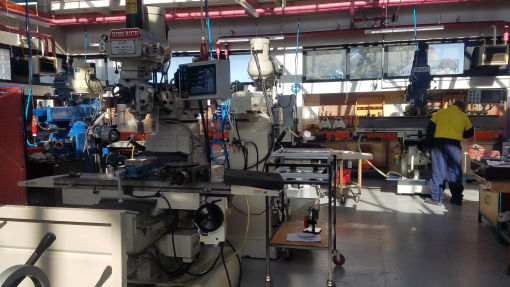

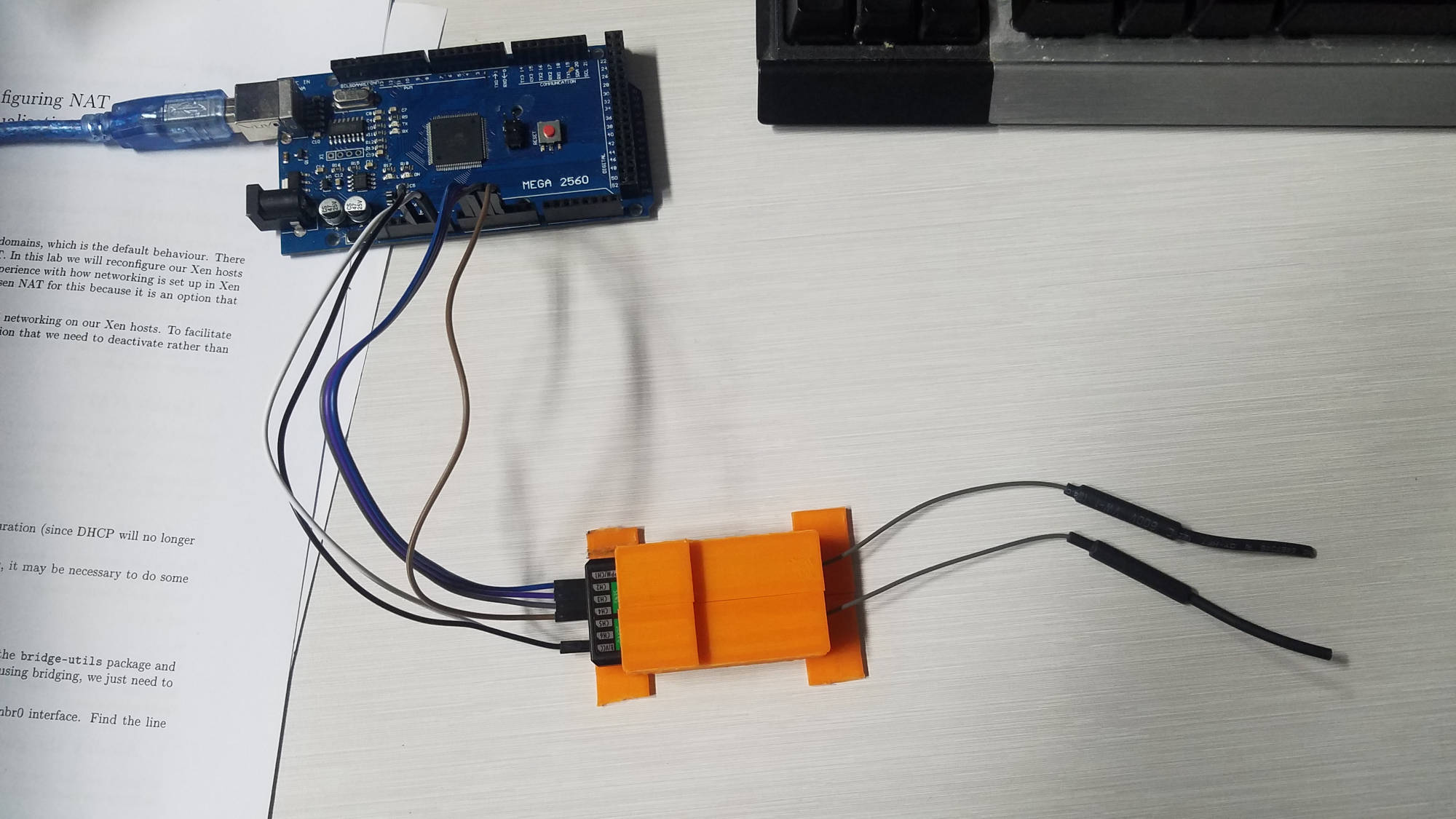

We began the process of gaining access to the engineering school's resources (EPICentre).